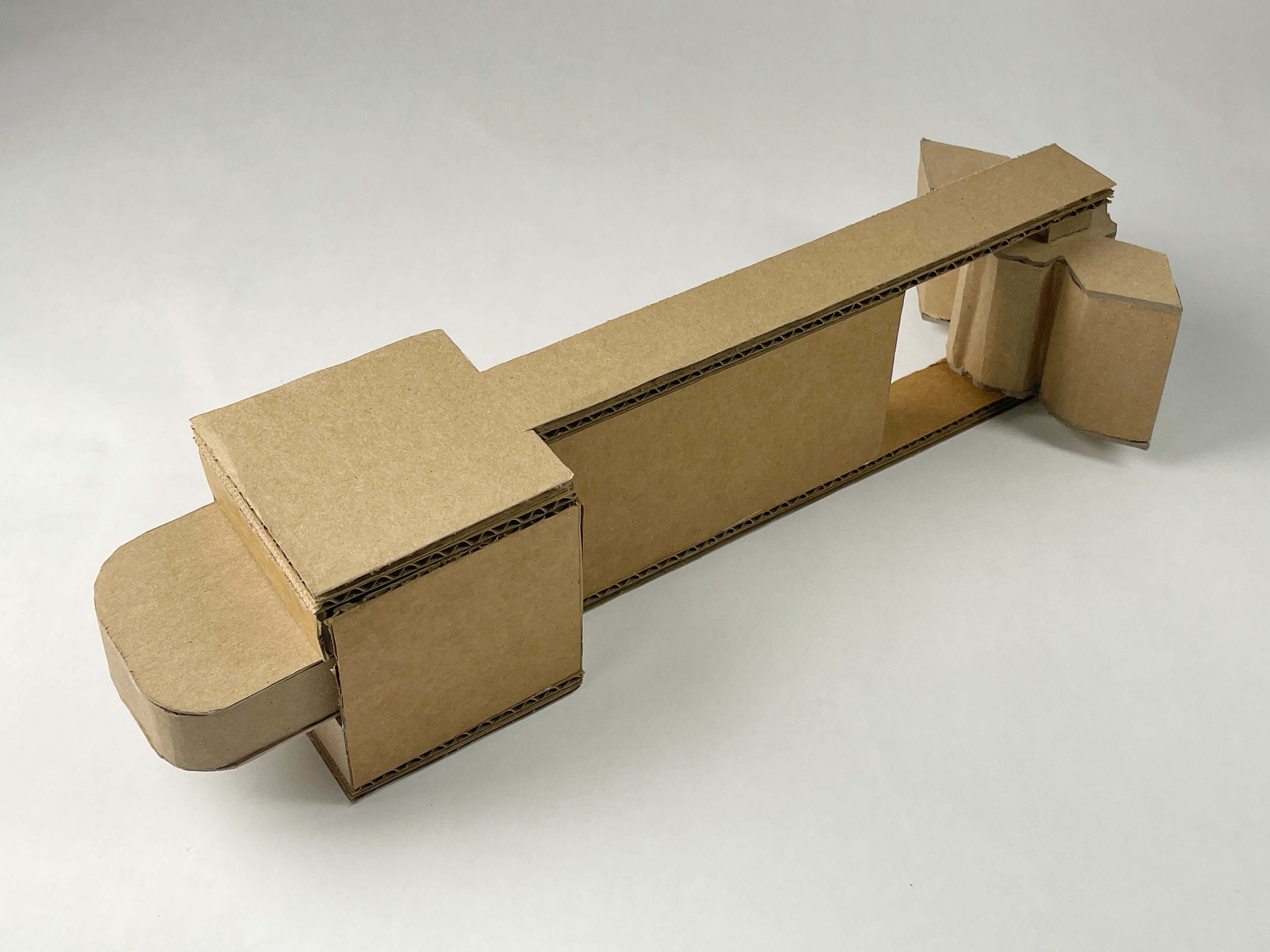

The prompt was to design individual objects based on specific constraints and work alongside a teammate to develop a temporary or reversible way to connect both of the objects

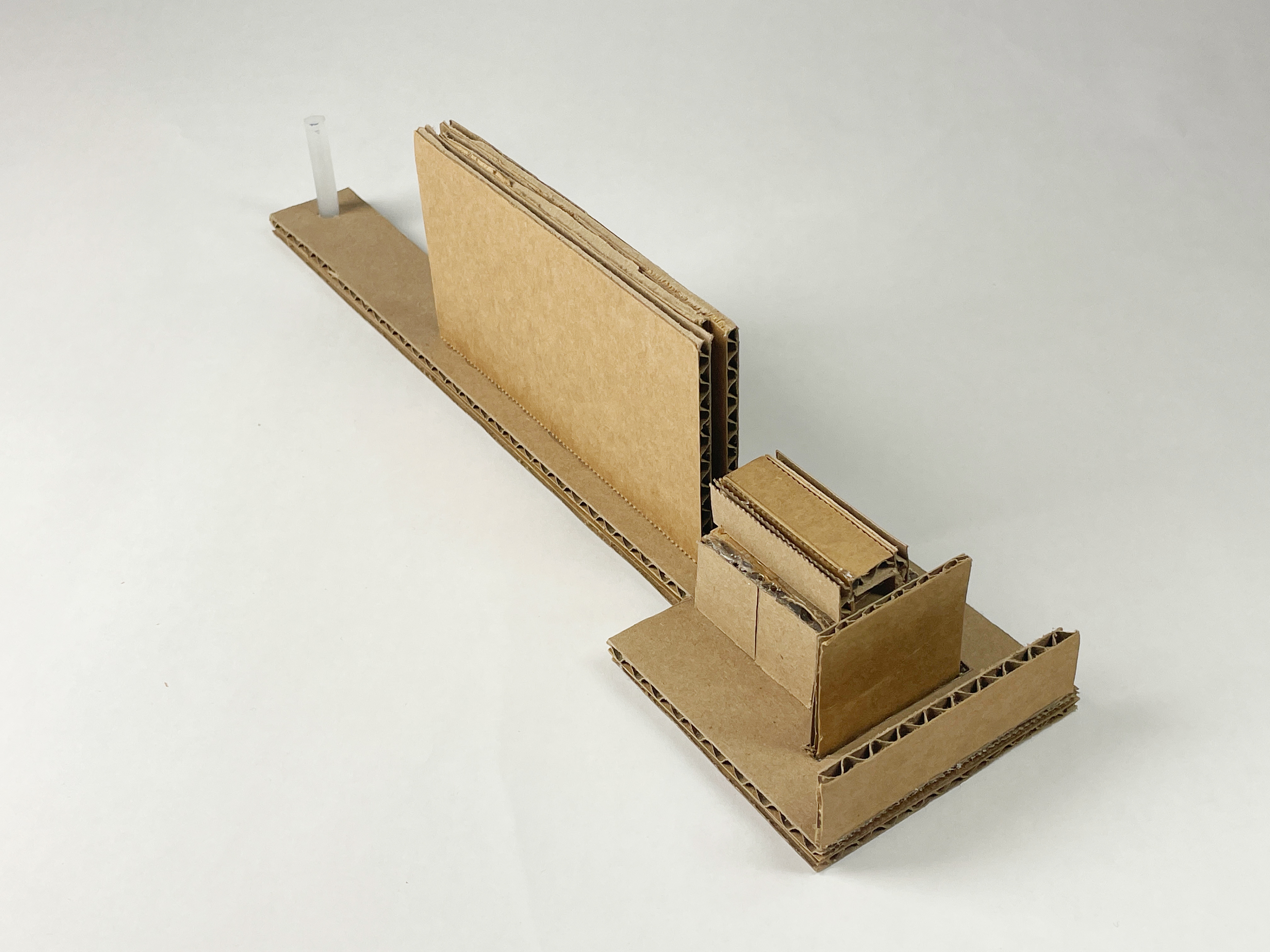

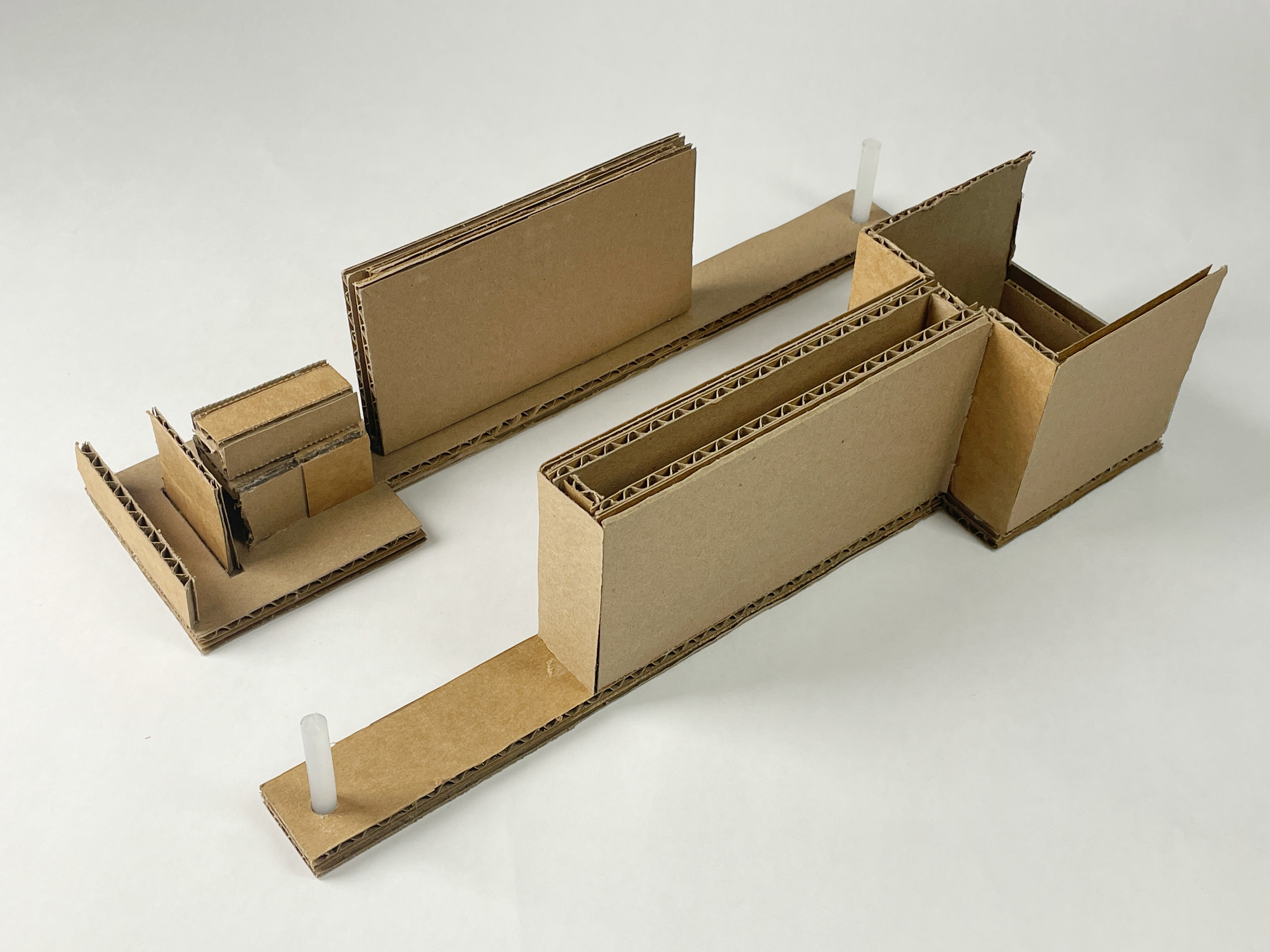

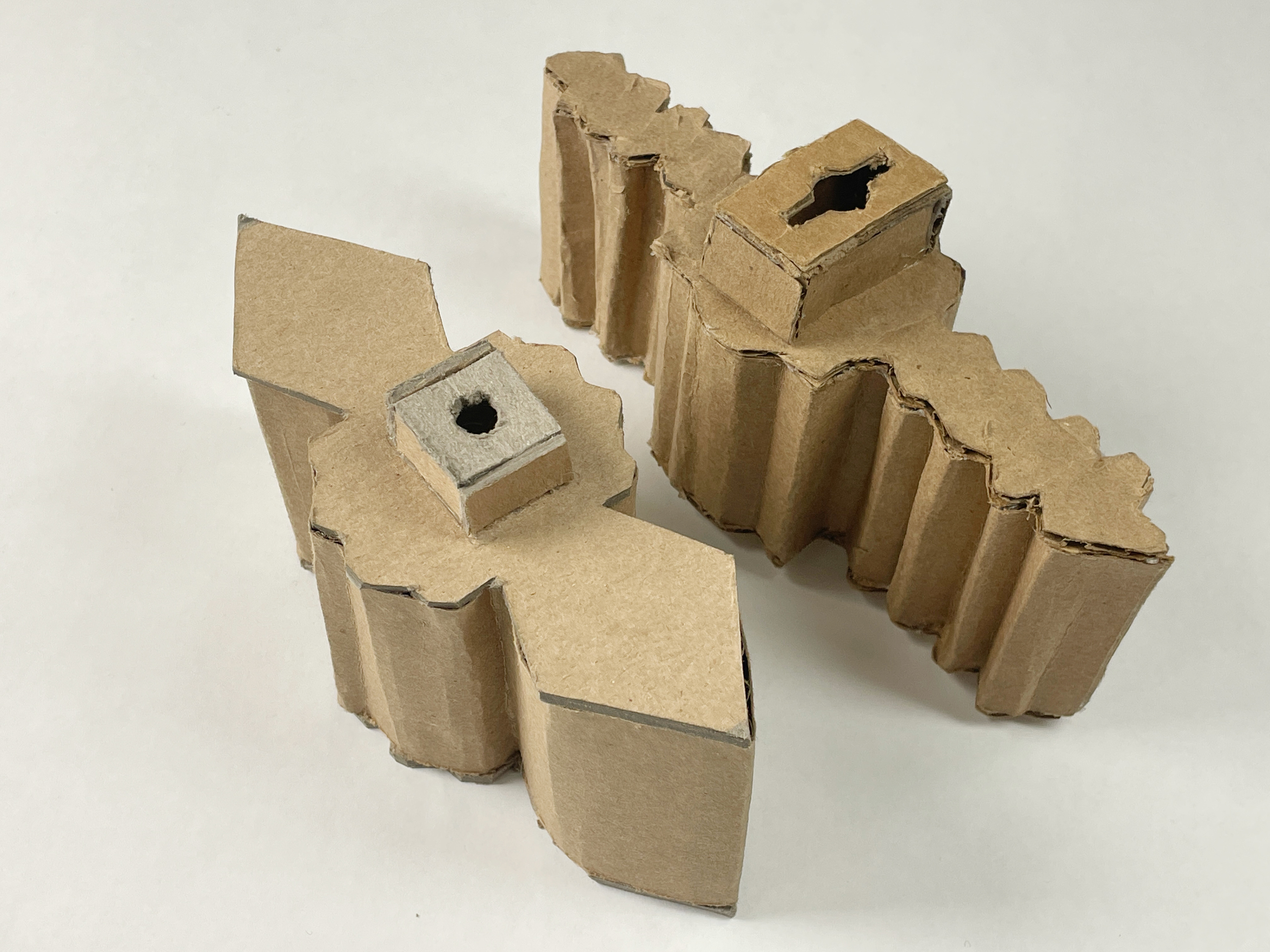

We researched and developed ideas, constructed quick low-fidelity prototypes, worked as a team and collaborated, and iterated our models based on feedback. Our final connection enclosed one of our objects snugly and made the second object rotate along an axis. The final design is minimalist and simple but versatile and satisfying, connecting both objects and snapping on tightly and comfortably.

Process

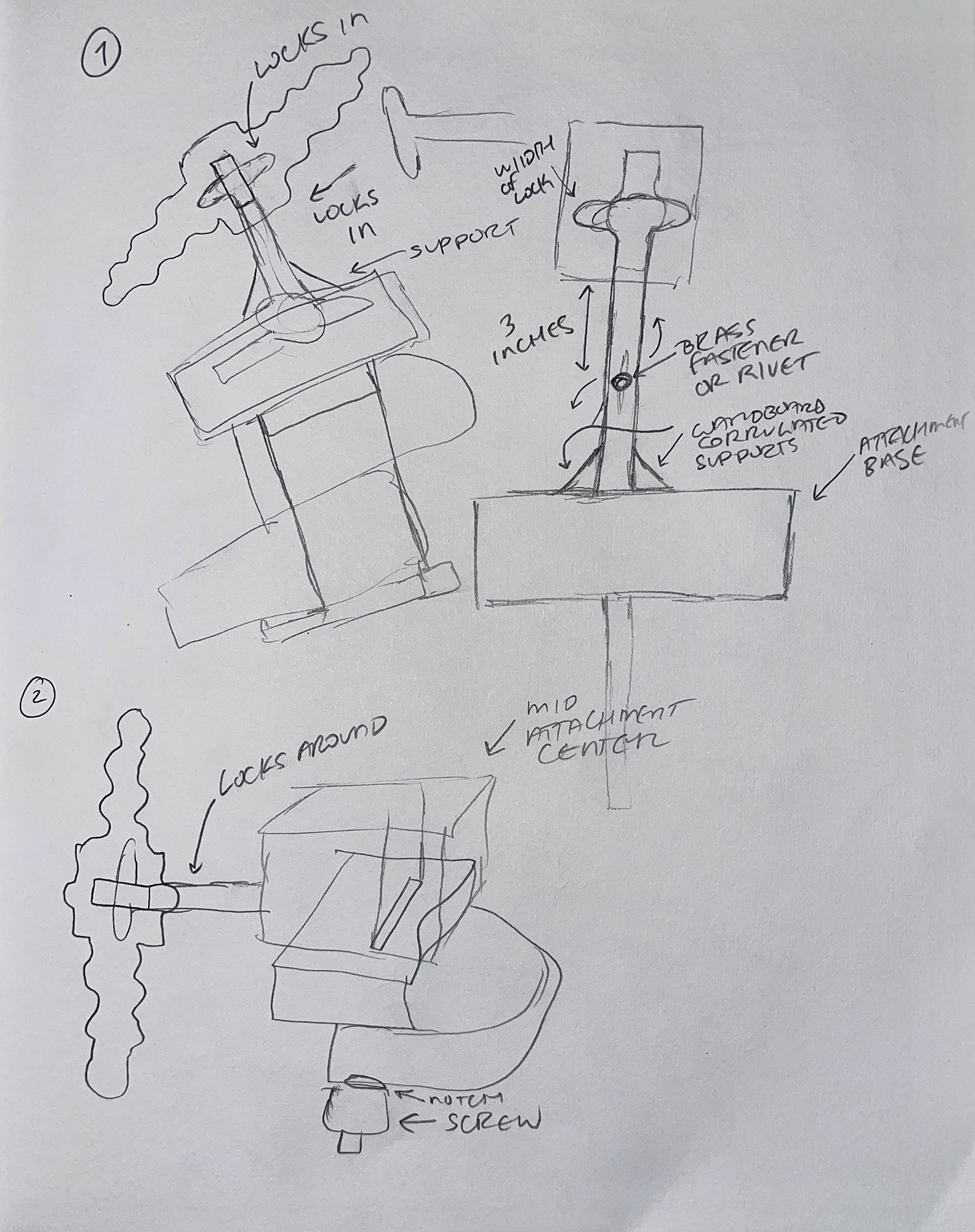

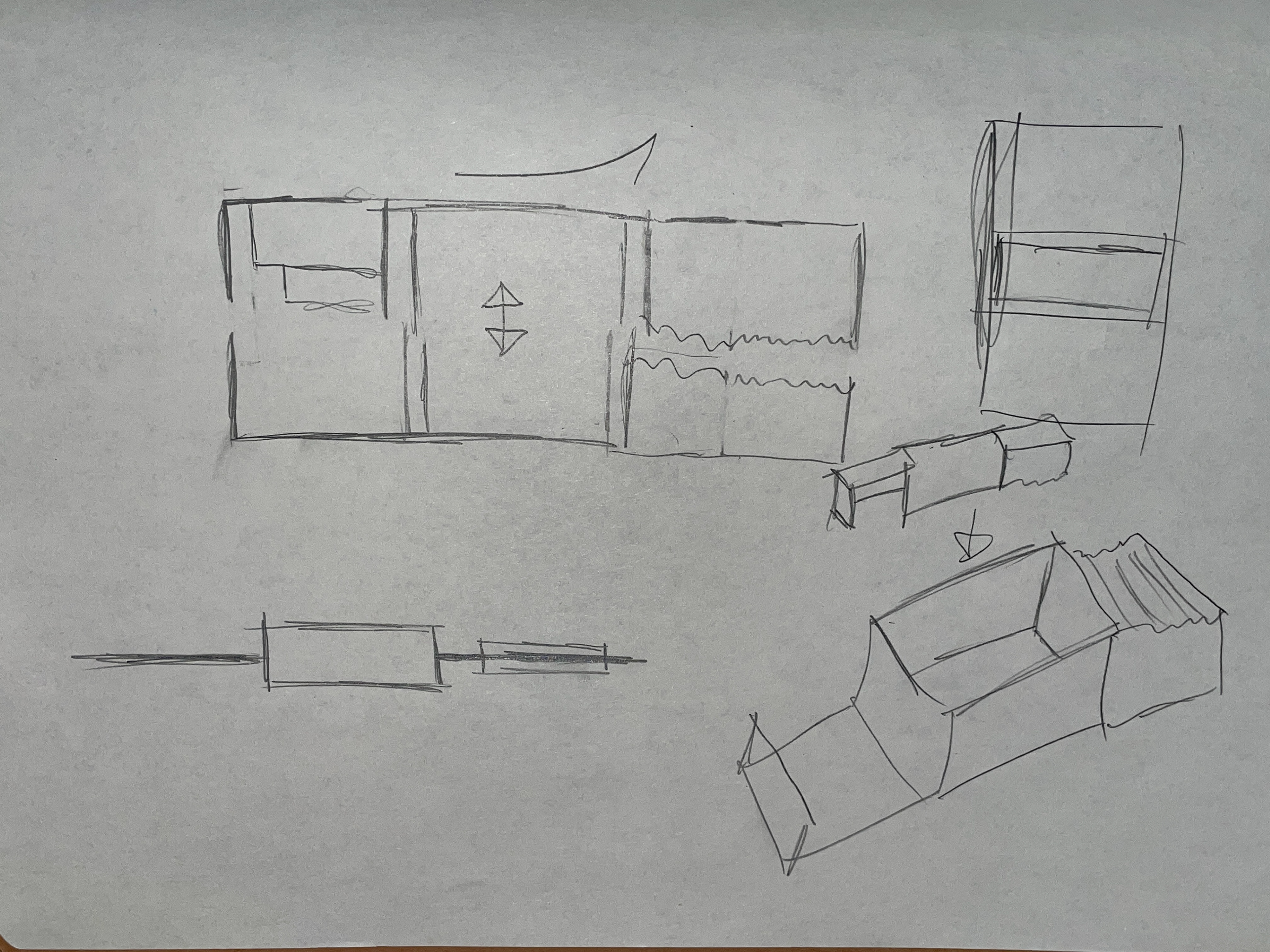

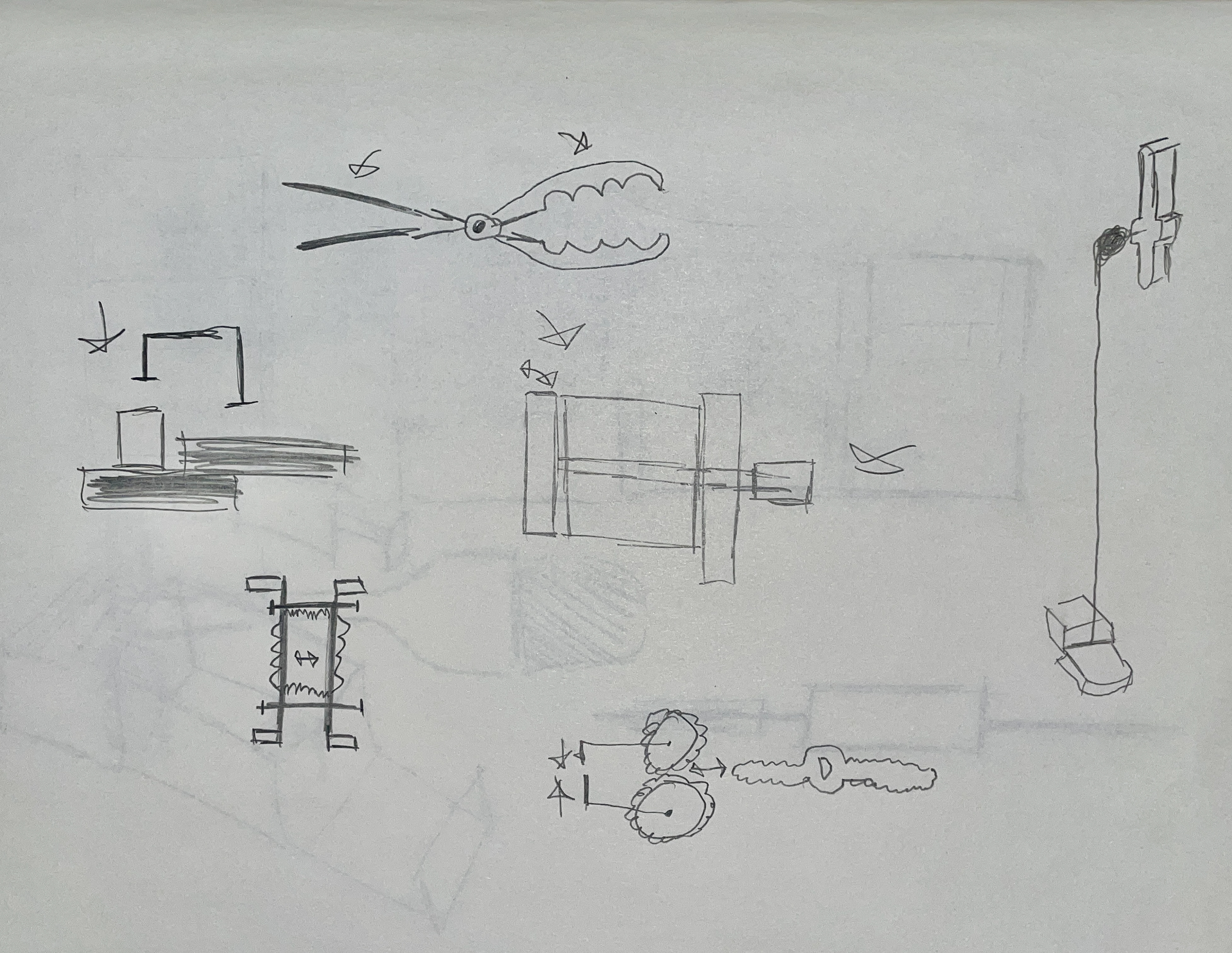

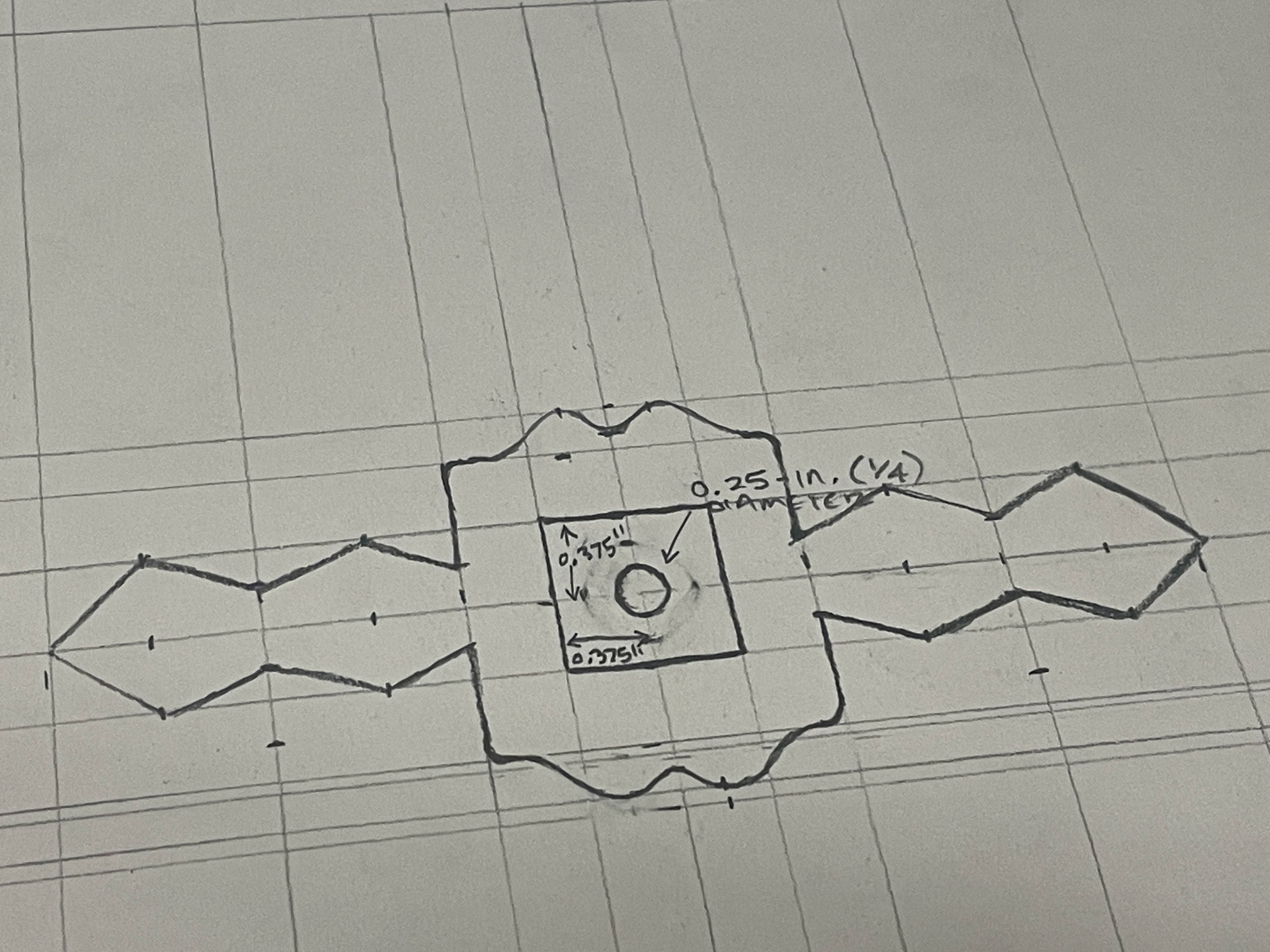

(1) Brainstorming possible connections and leveraging the shape of the objects for connections.

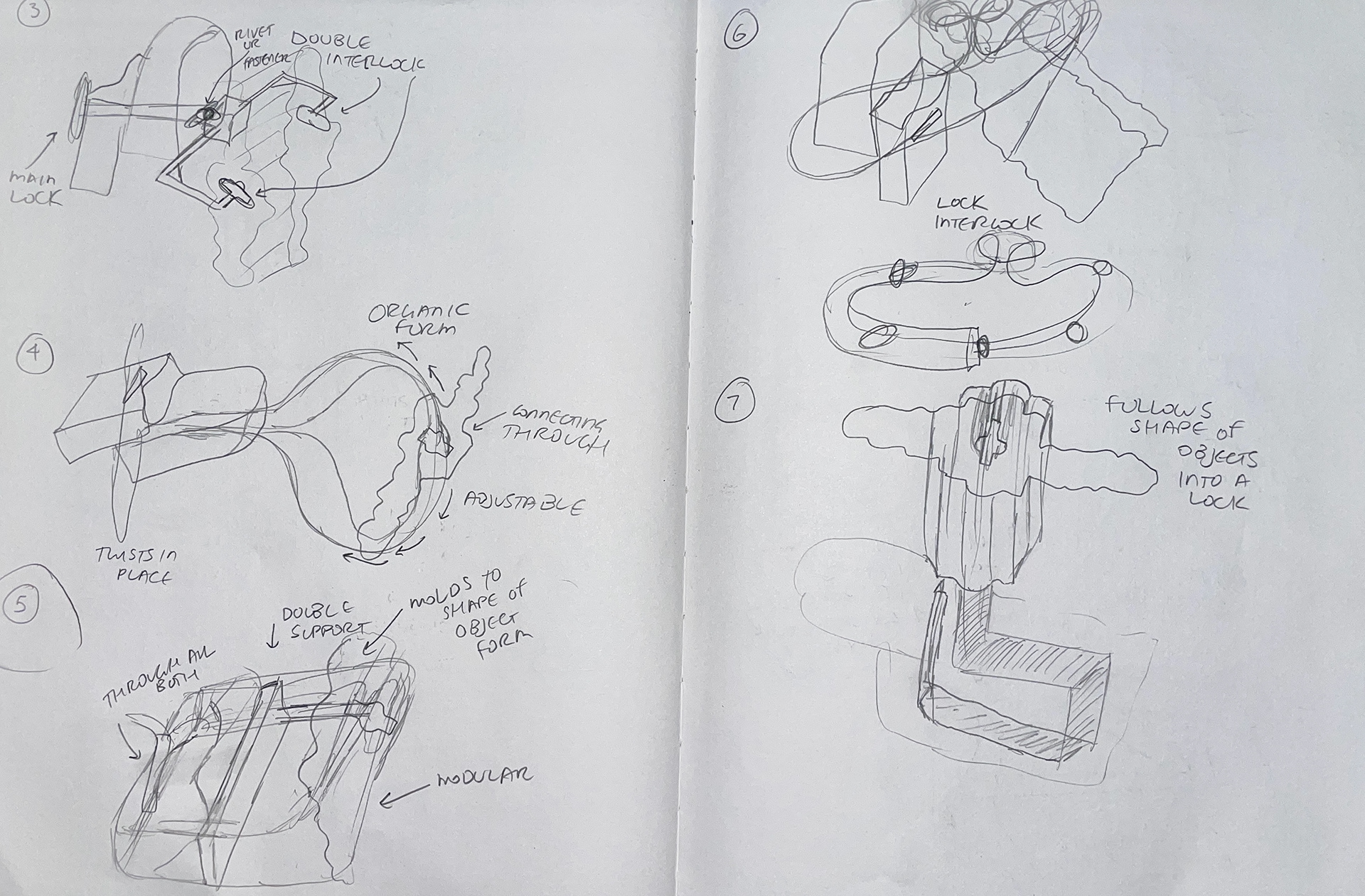

(2) Conceptual sketches including form and mechanisms.

(3) Selecting and focusing on the functionality of the final design.

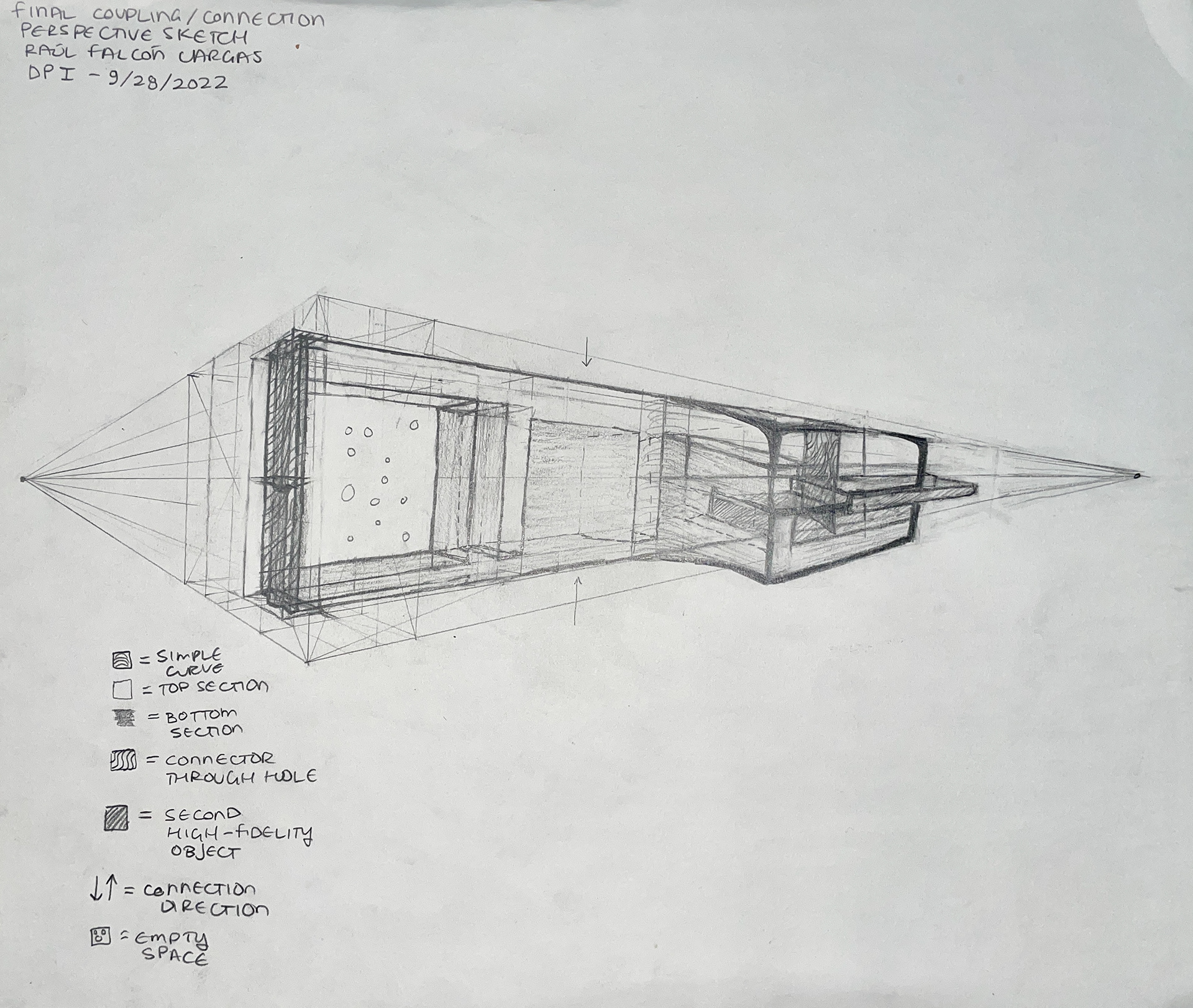

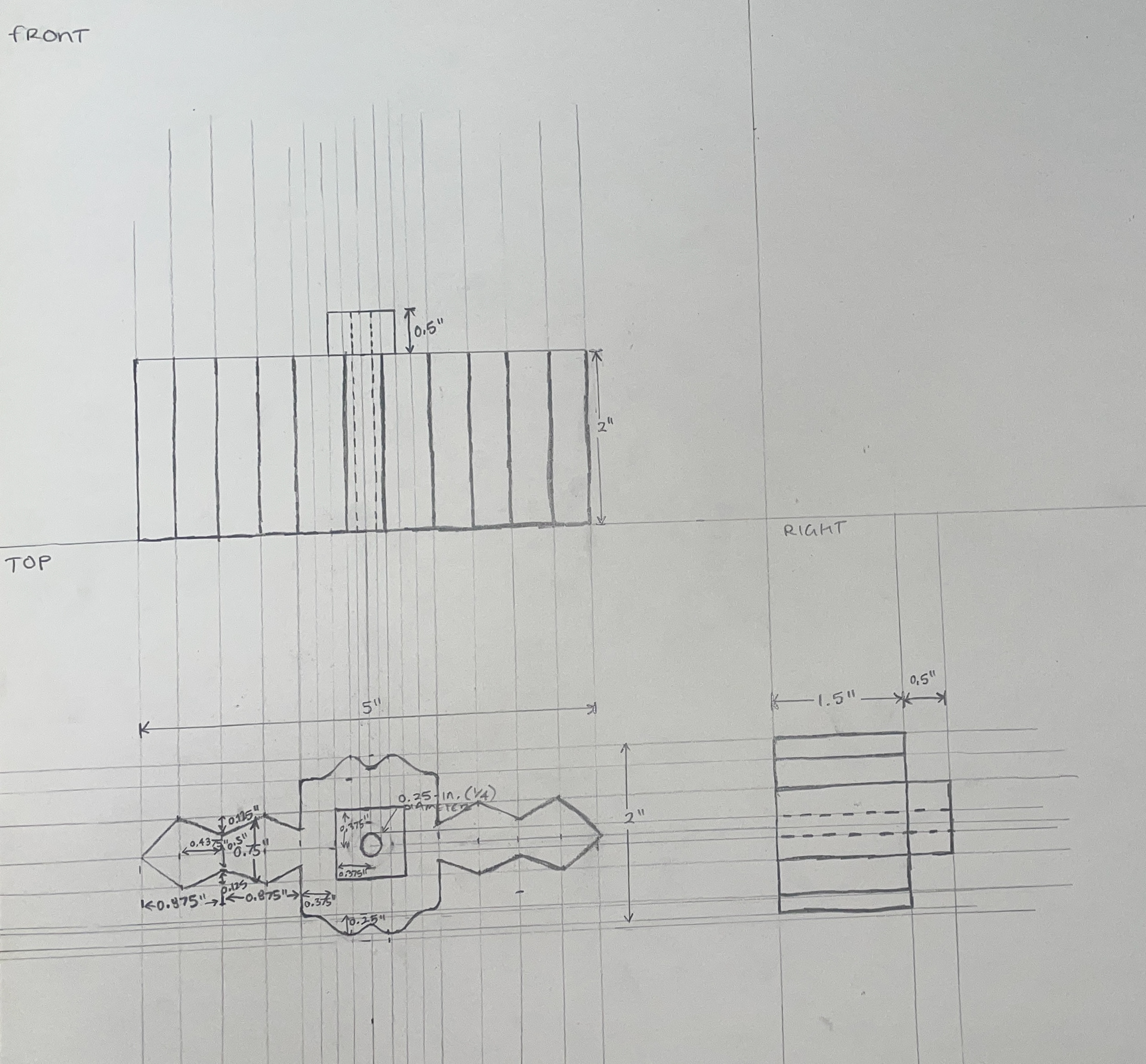

(4) Perspective drawings of initial connection mechanism

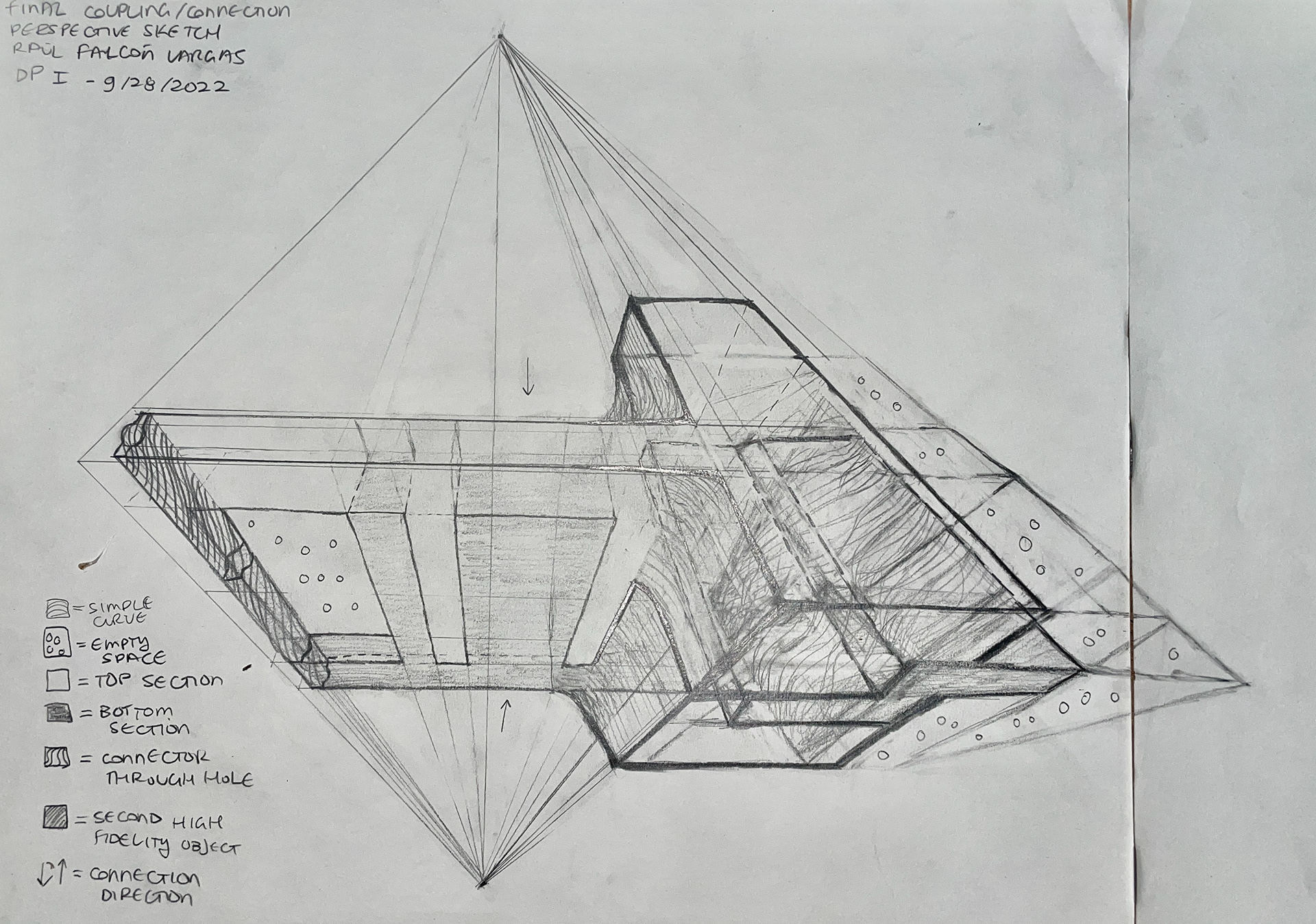

(5) Perspective drawing of new mechanism

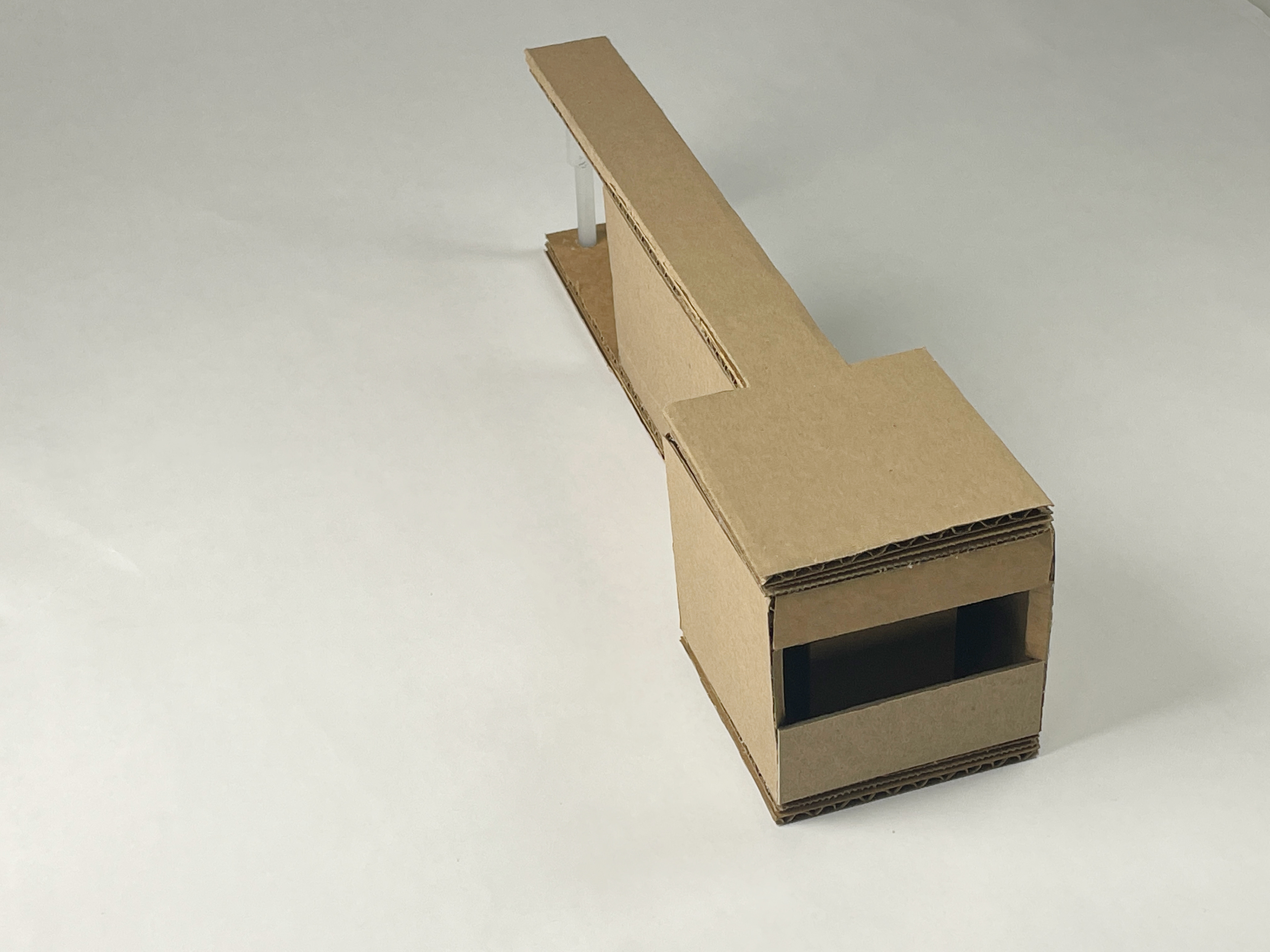

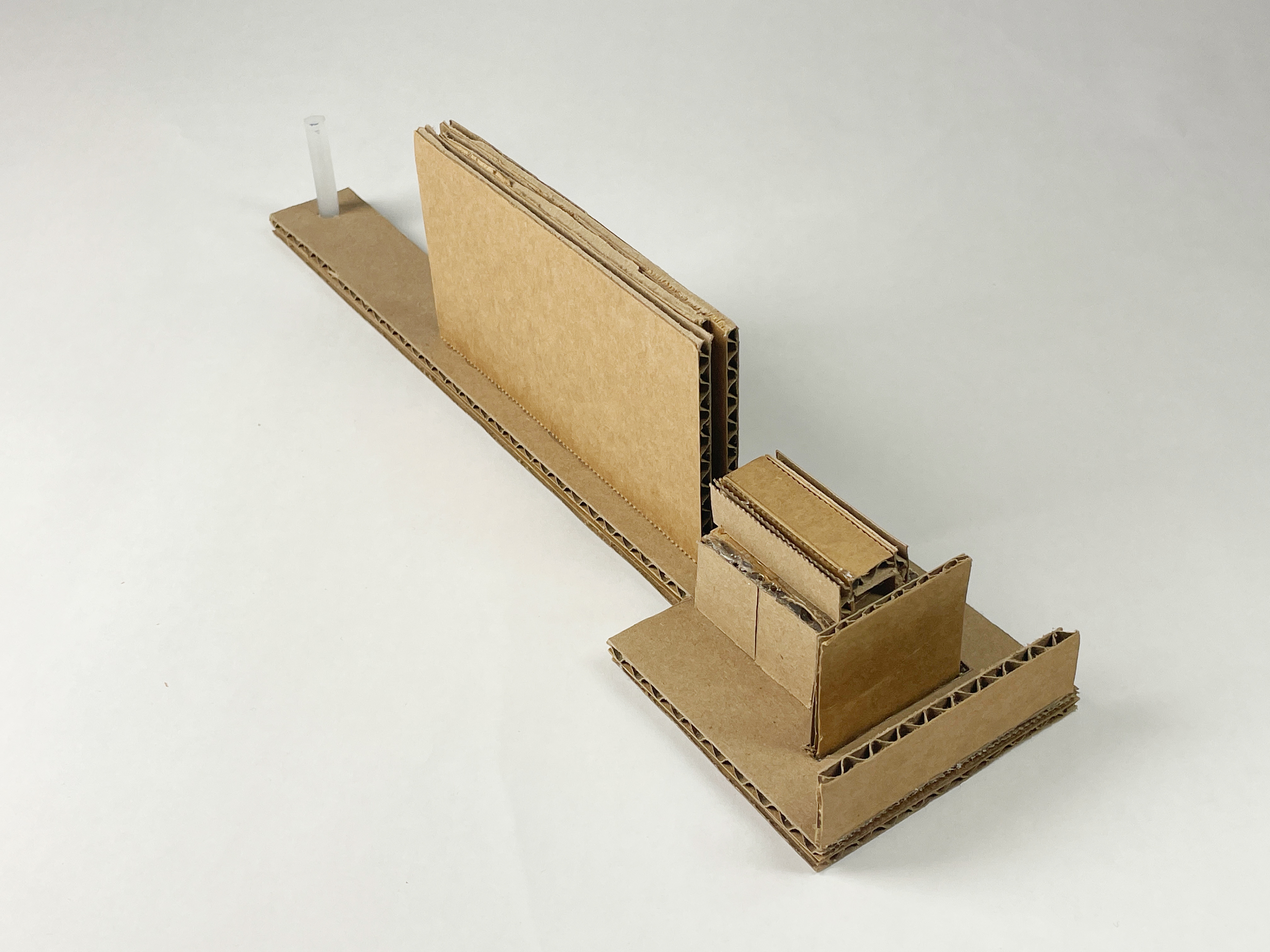

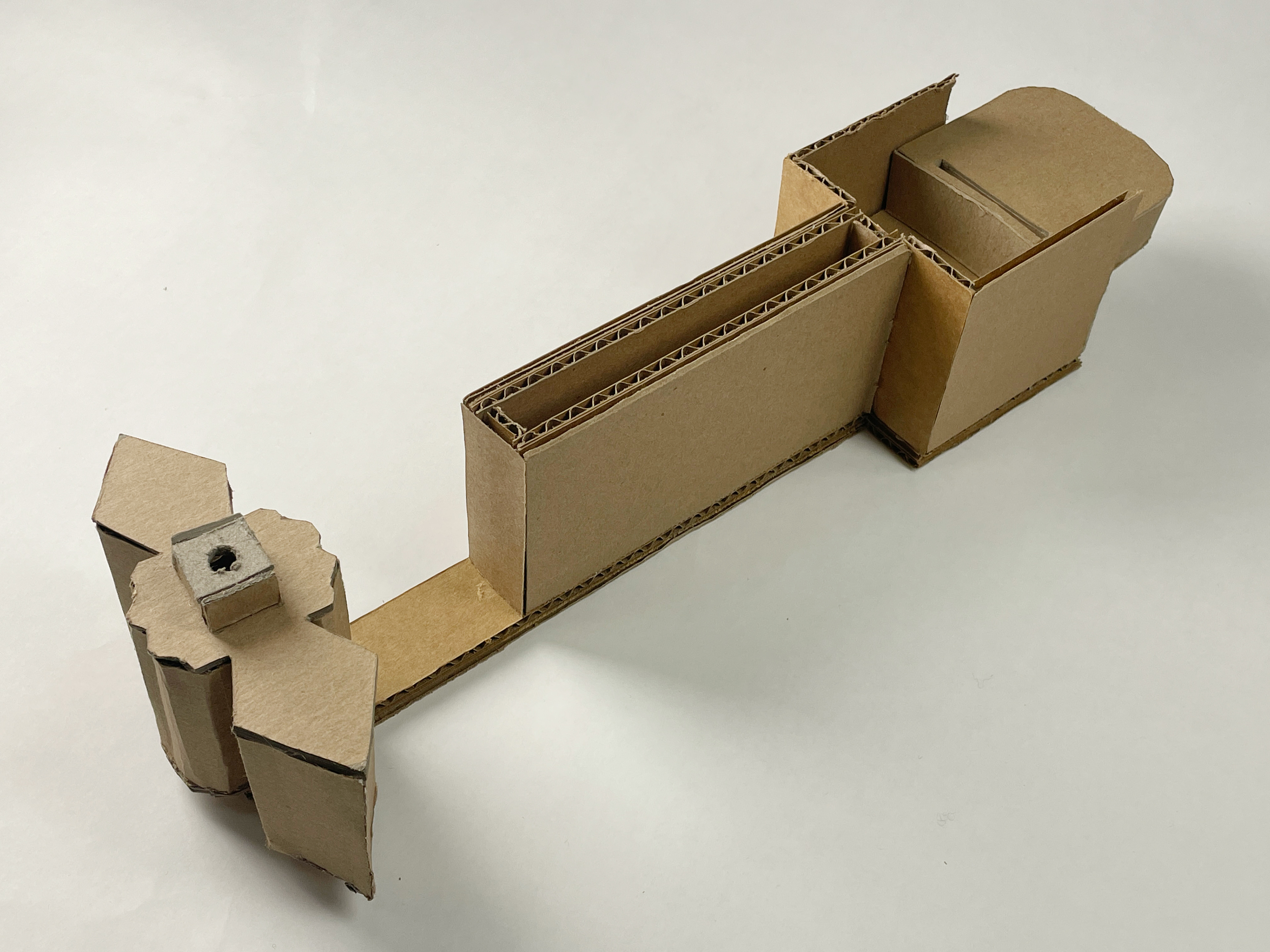

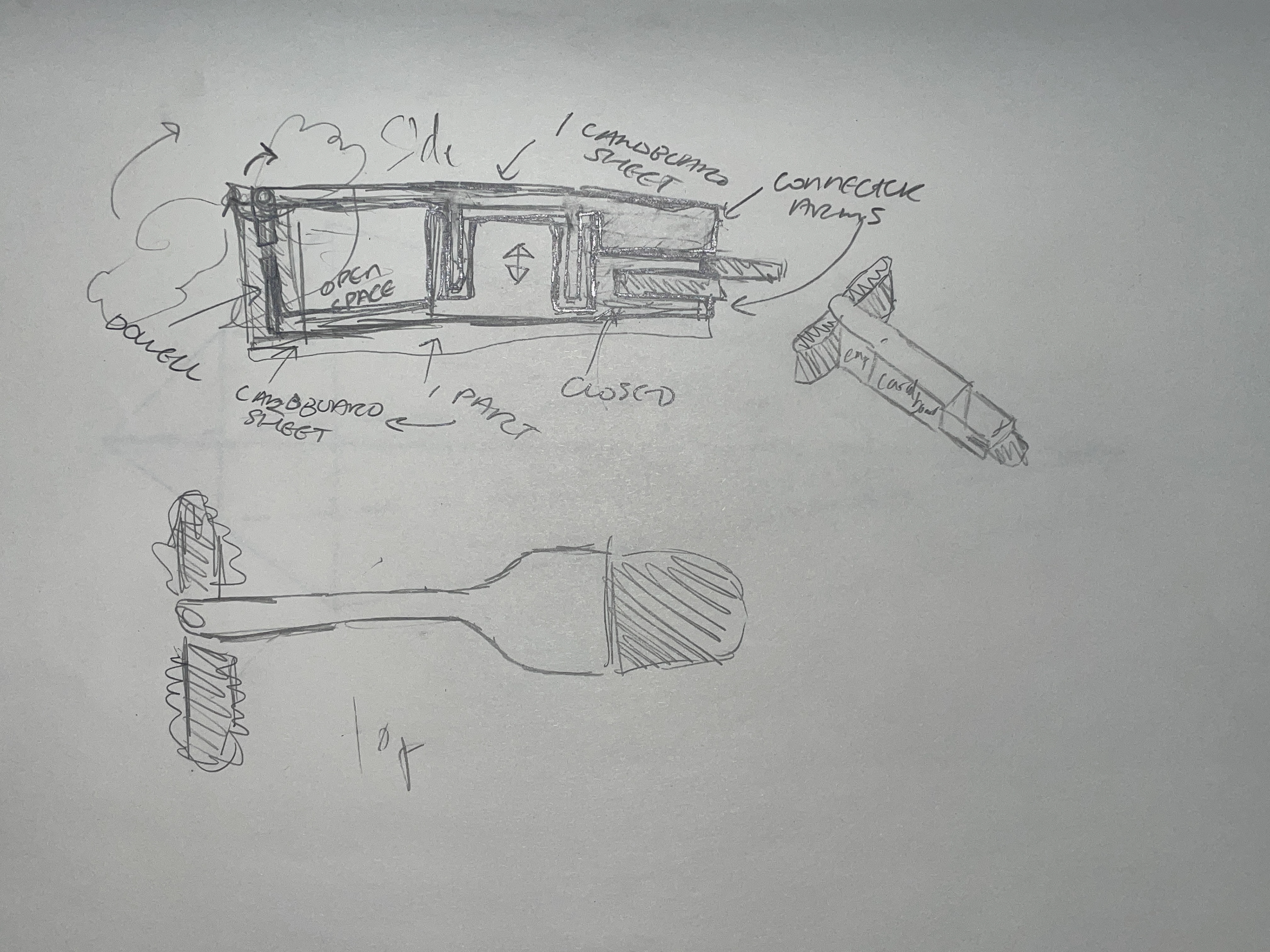

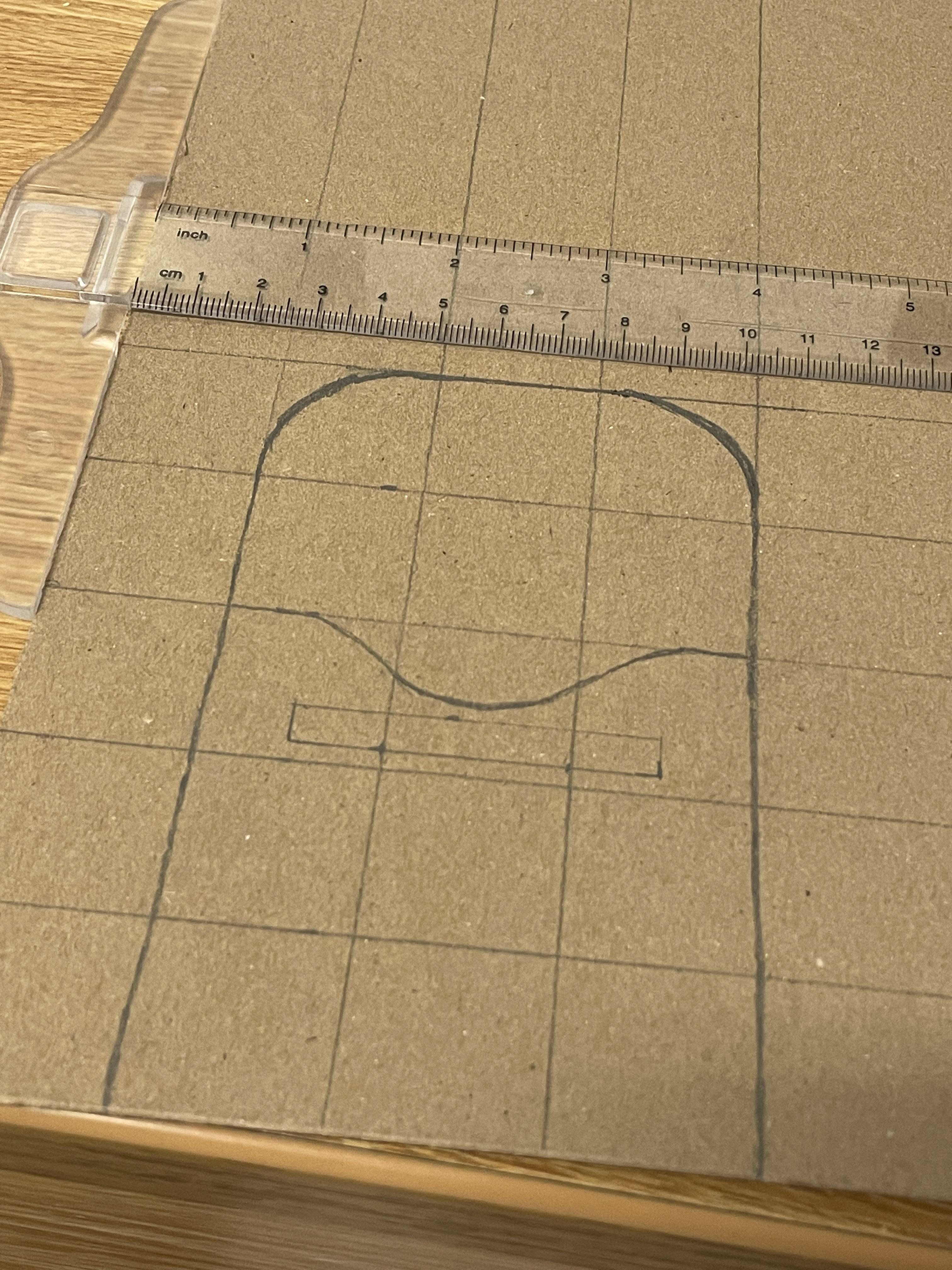

(6) We decided to make our objects even higher fidelity, so we began by modifying the previous high-fidelity model construction drawings. Based on learning about cardboard’s properties (the greater the thickness the more rigid), I set out to devise a way to leverage and use those as design considerations for developing our model.

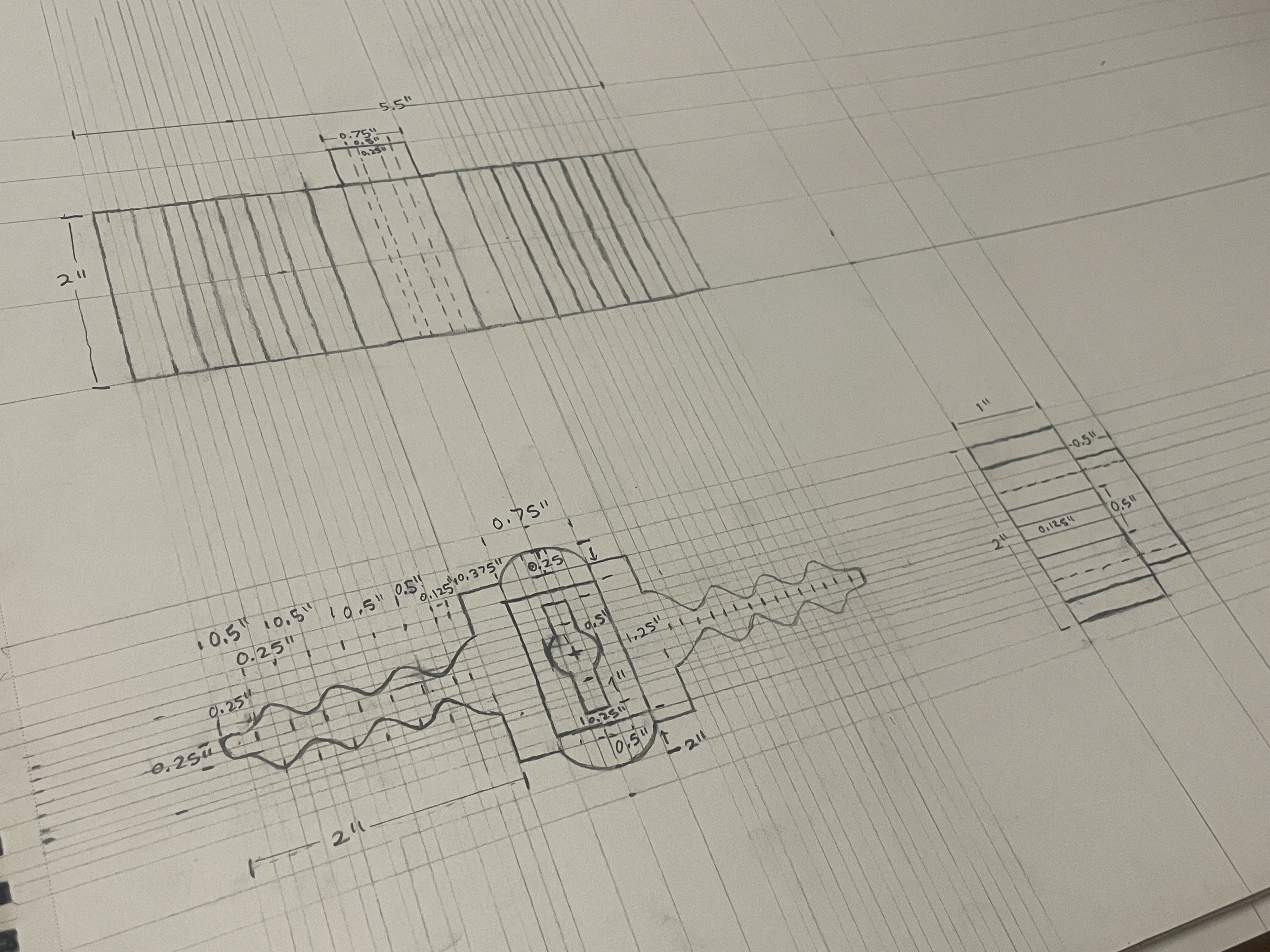

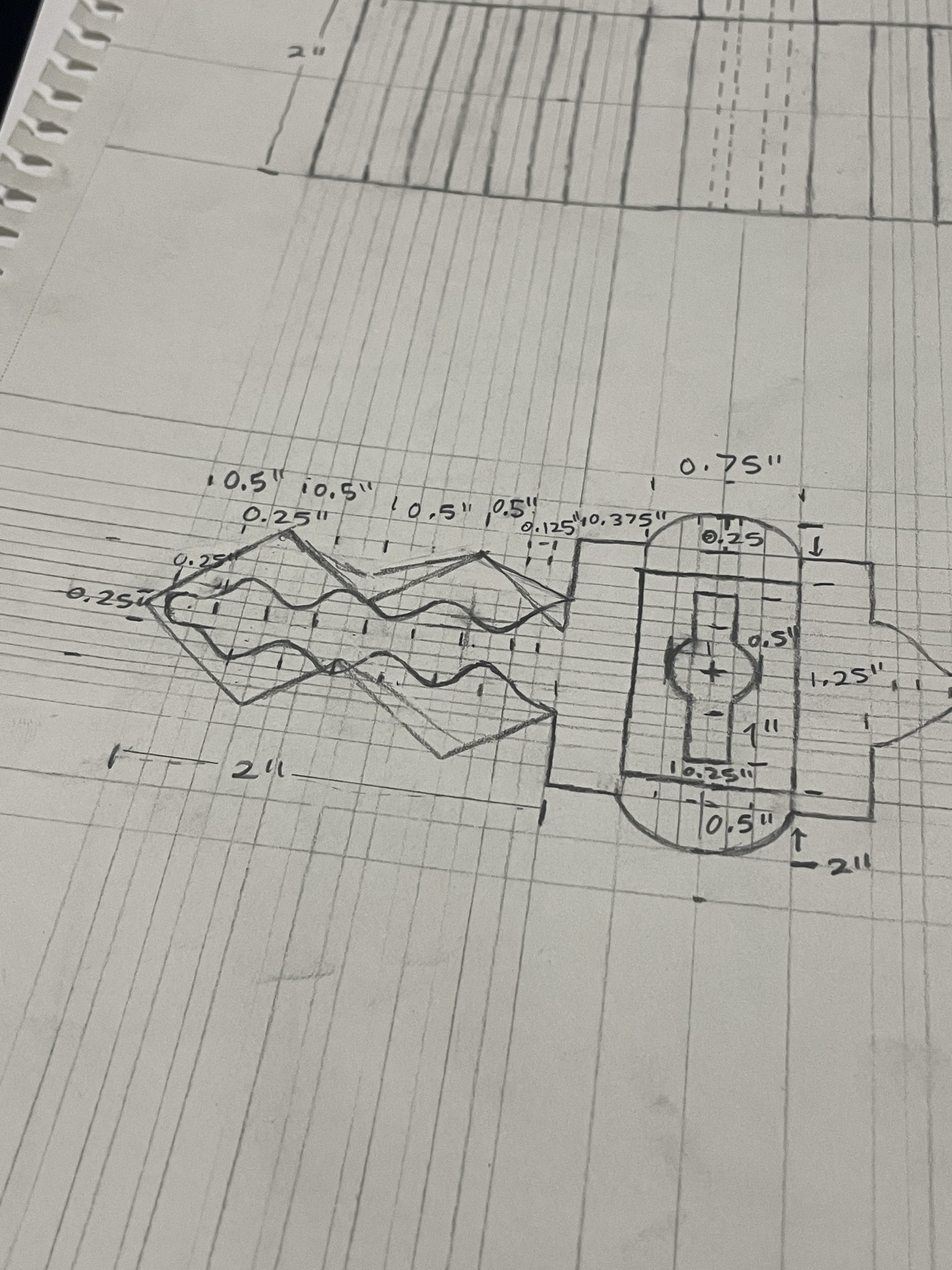

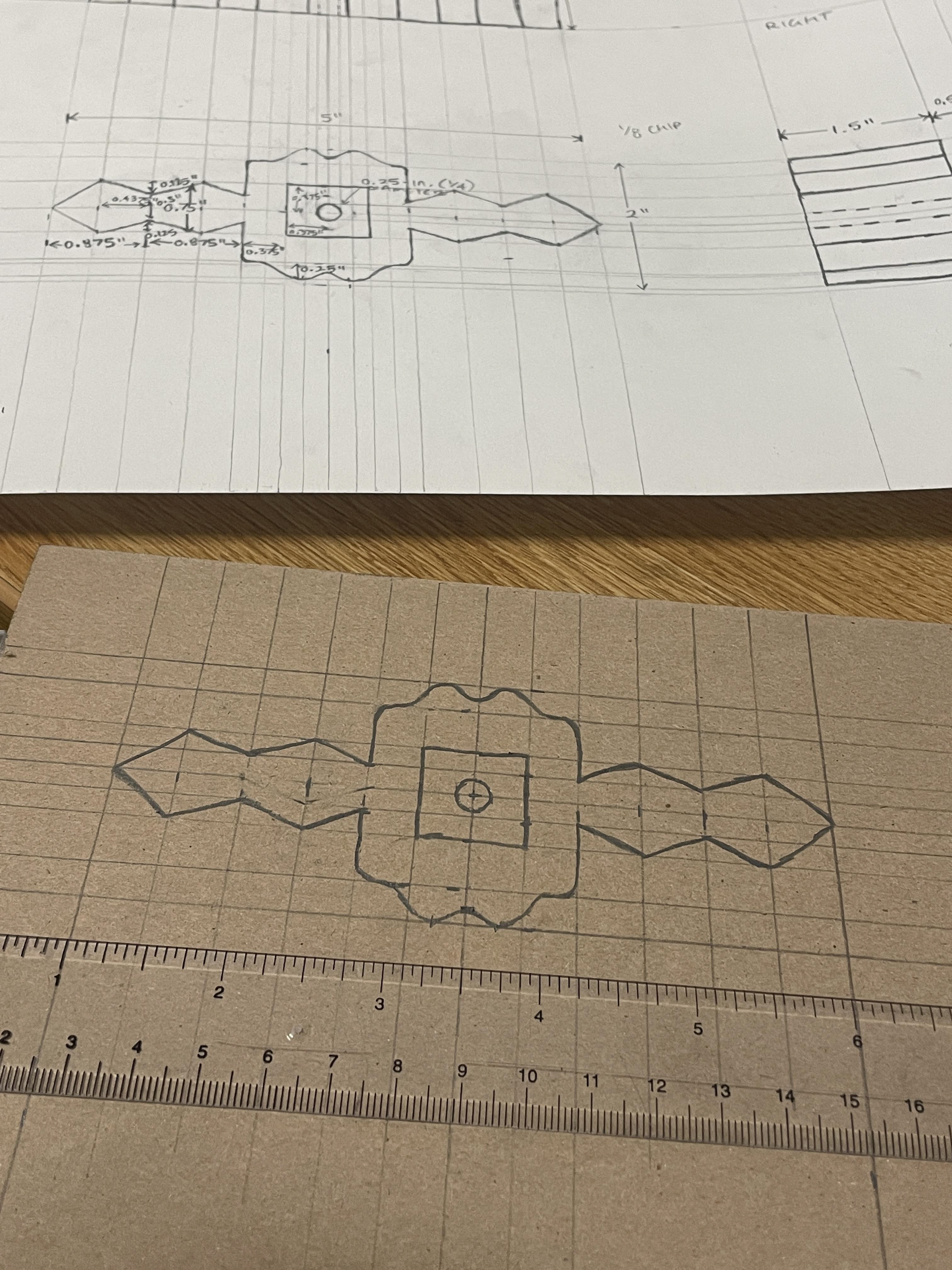

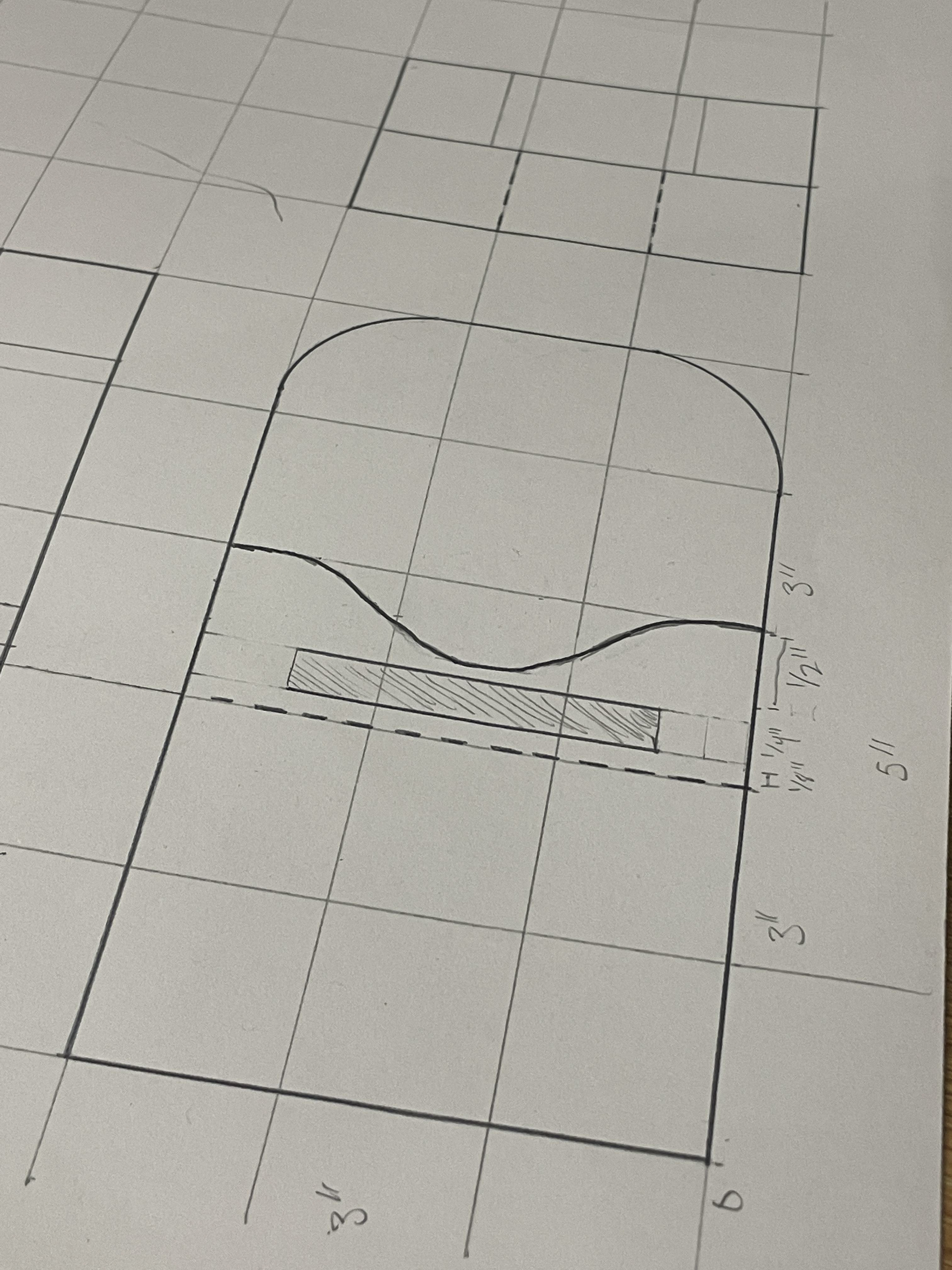

(7) New construction drawing with design considerations, with guide measurements to guide easy replication in cardboard.

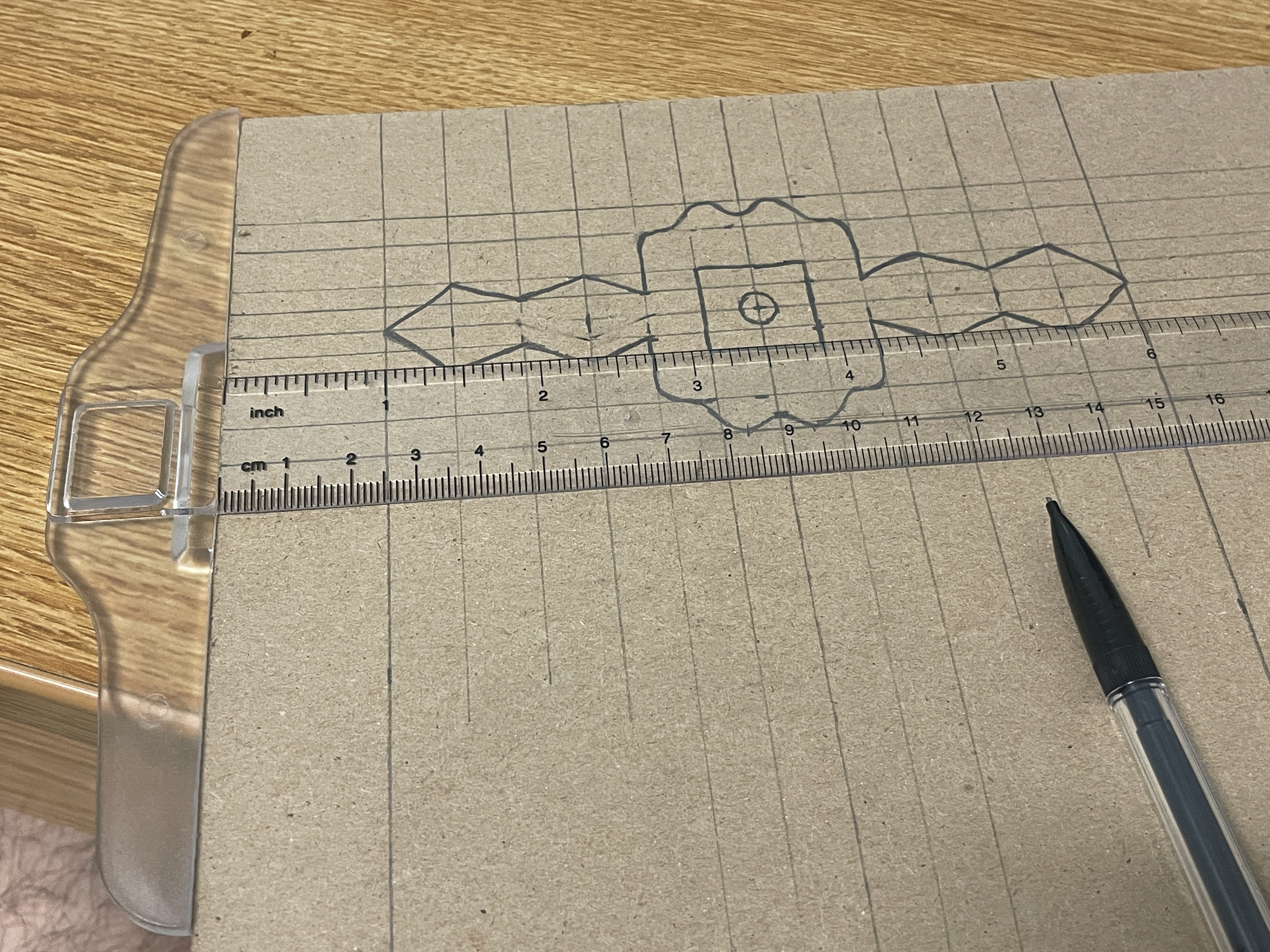

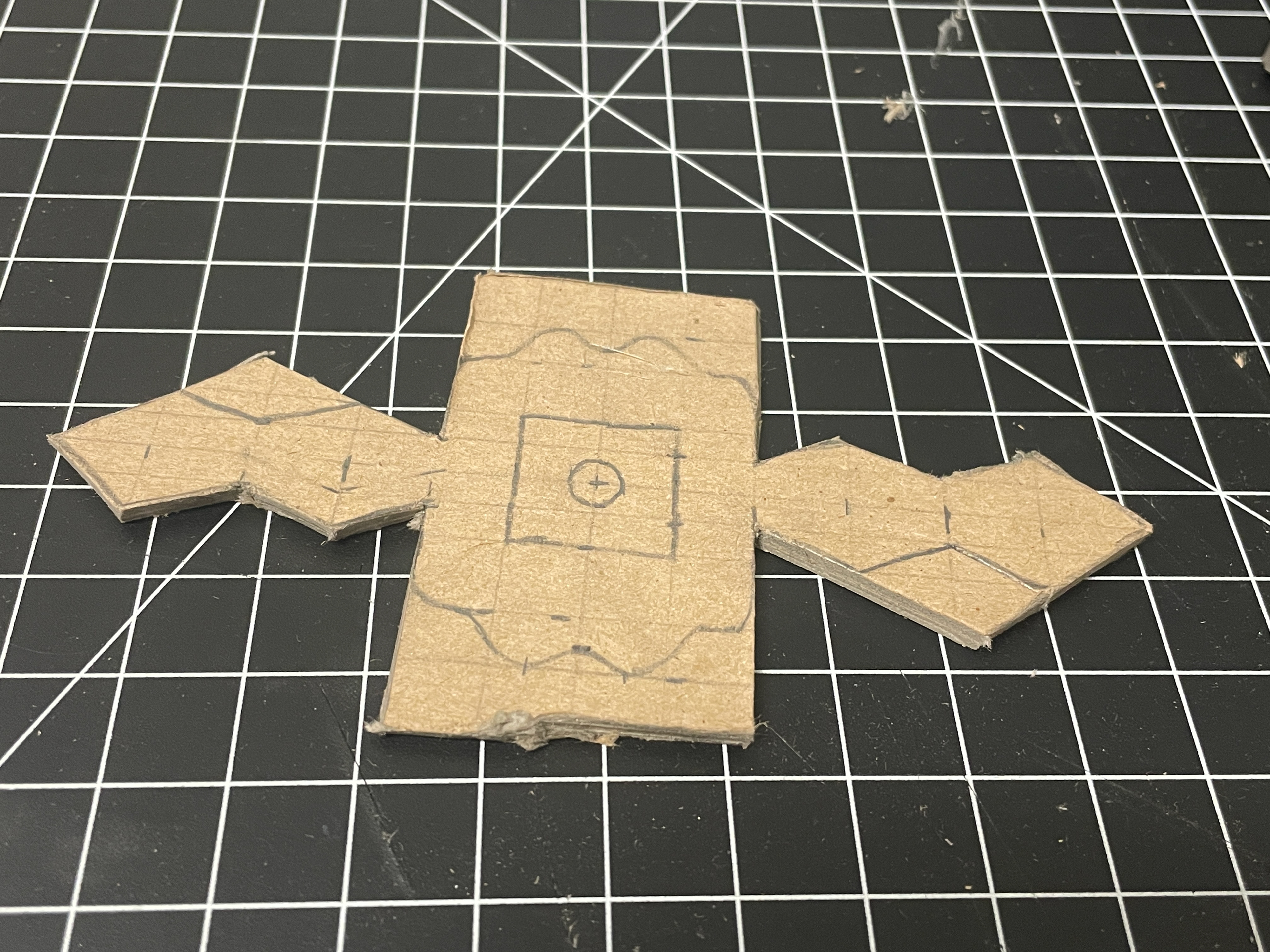

(8) Replication in cardboard based on guide measurements in construction drawing… smooth workflow.

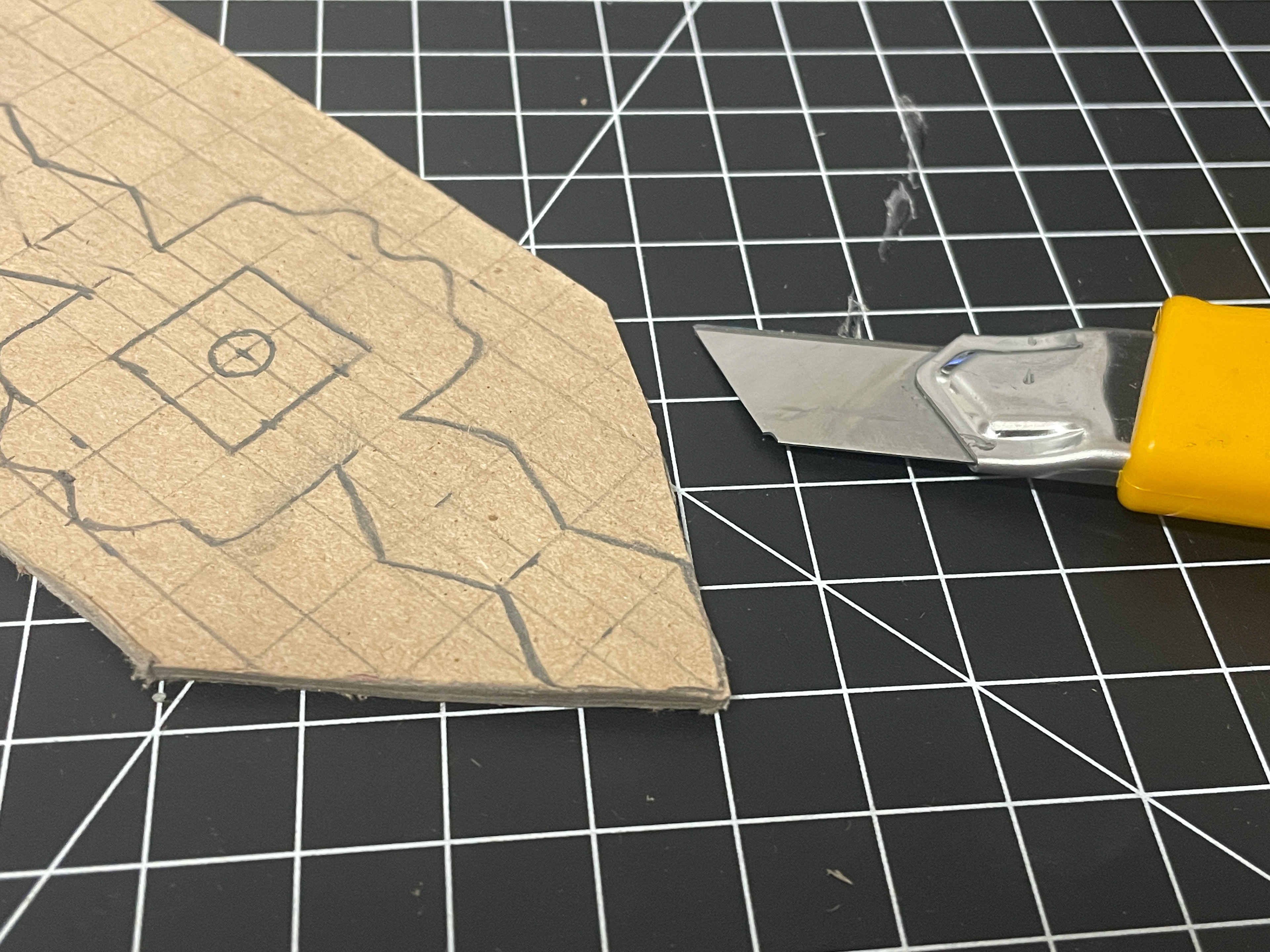

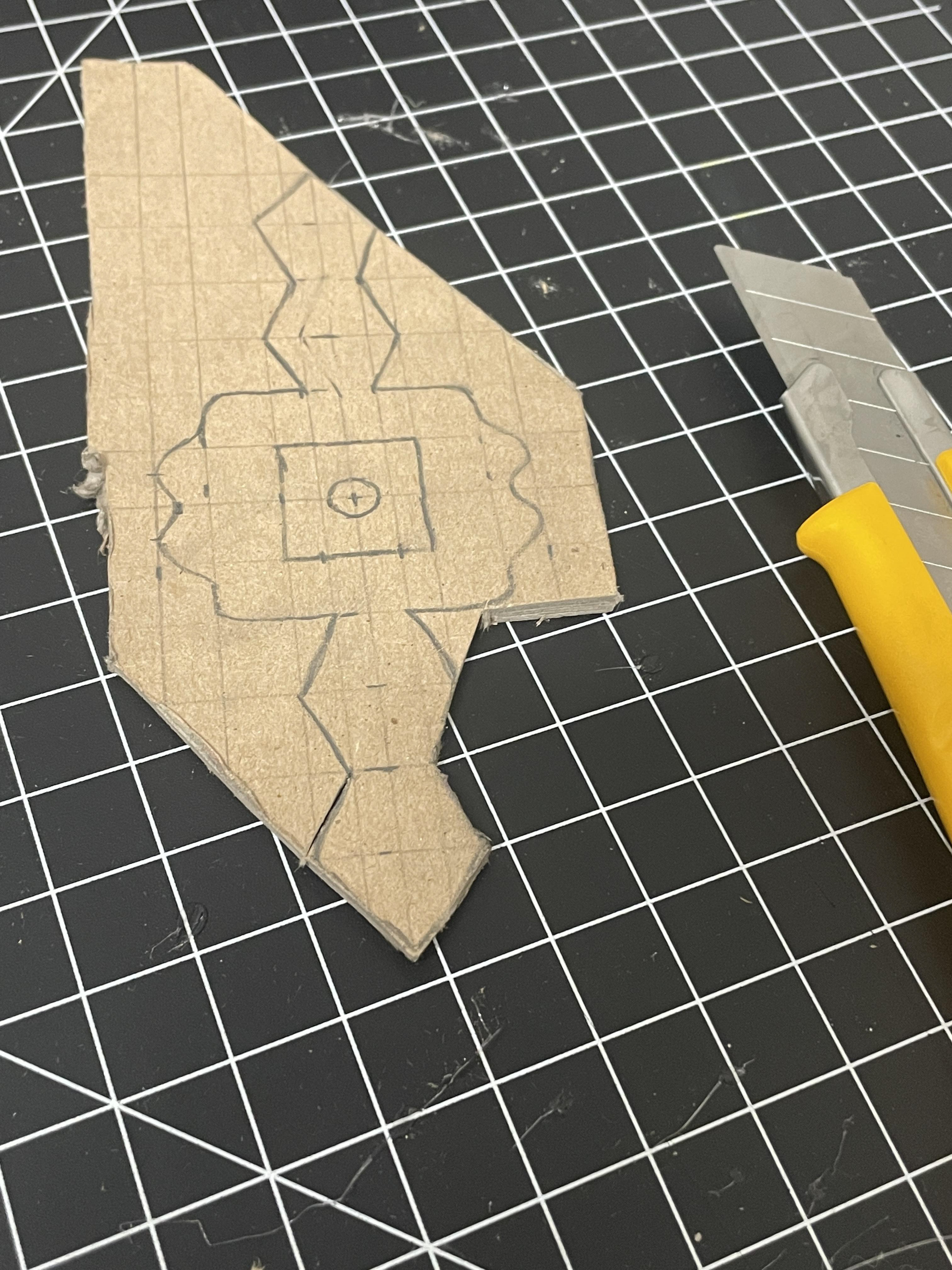

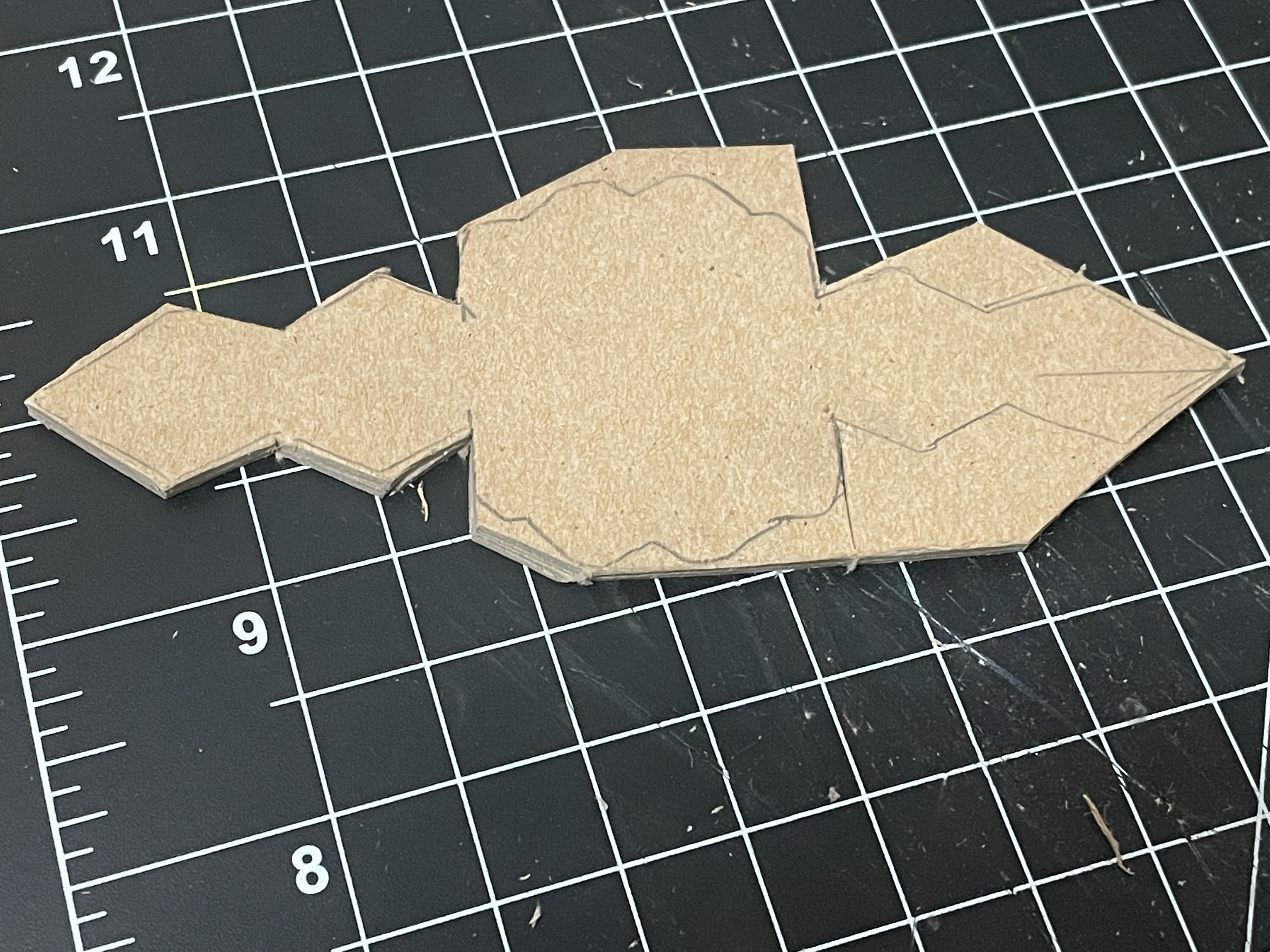

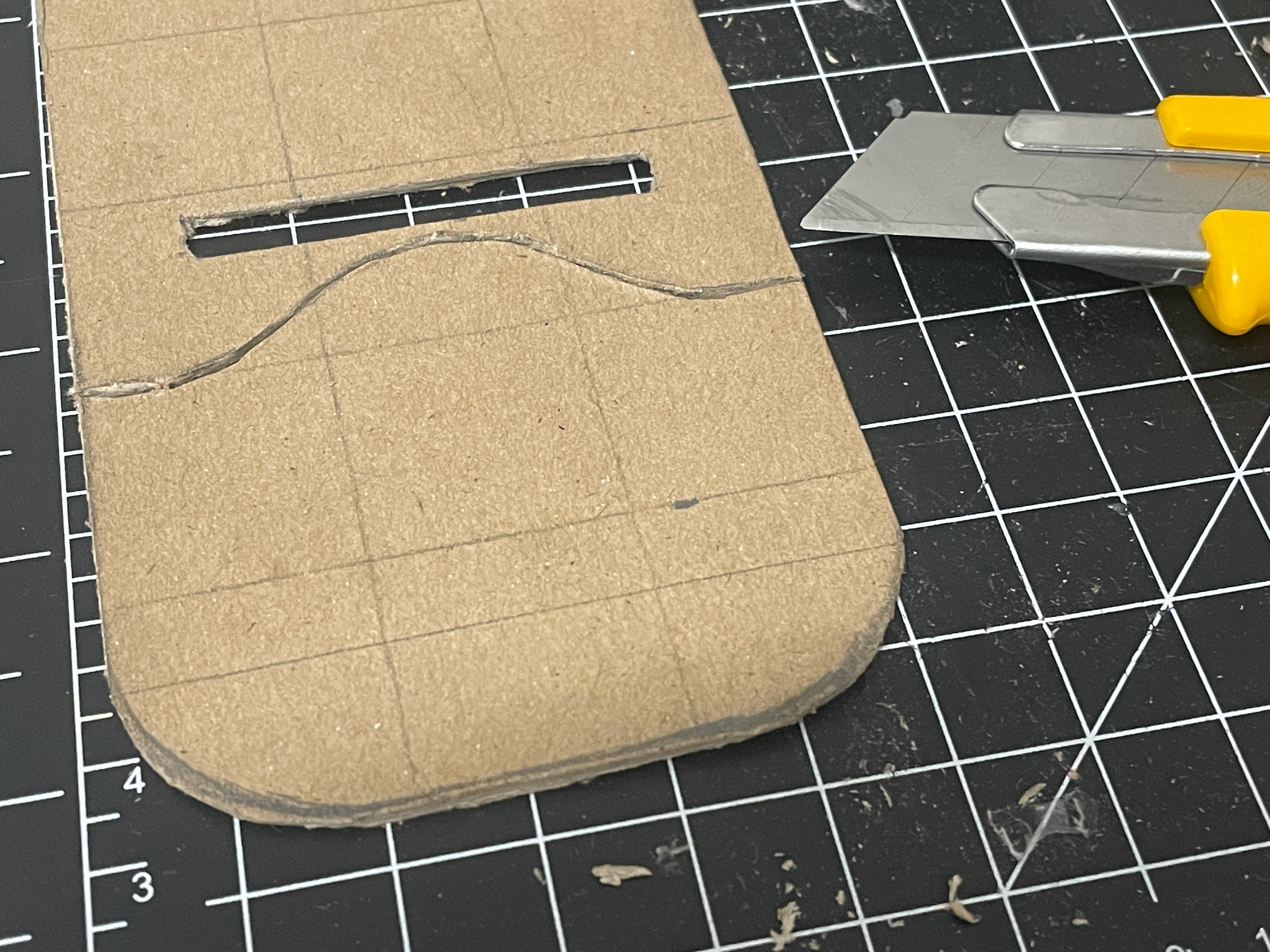

(9) Cutting to make less handling errors by cutting bigger chunks at angles rather than increasingly curvy and hard to cut shapes that would damage the cardboard… leveraging our data to make a high-fidelity model easily.

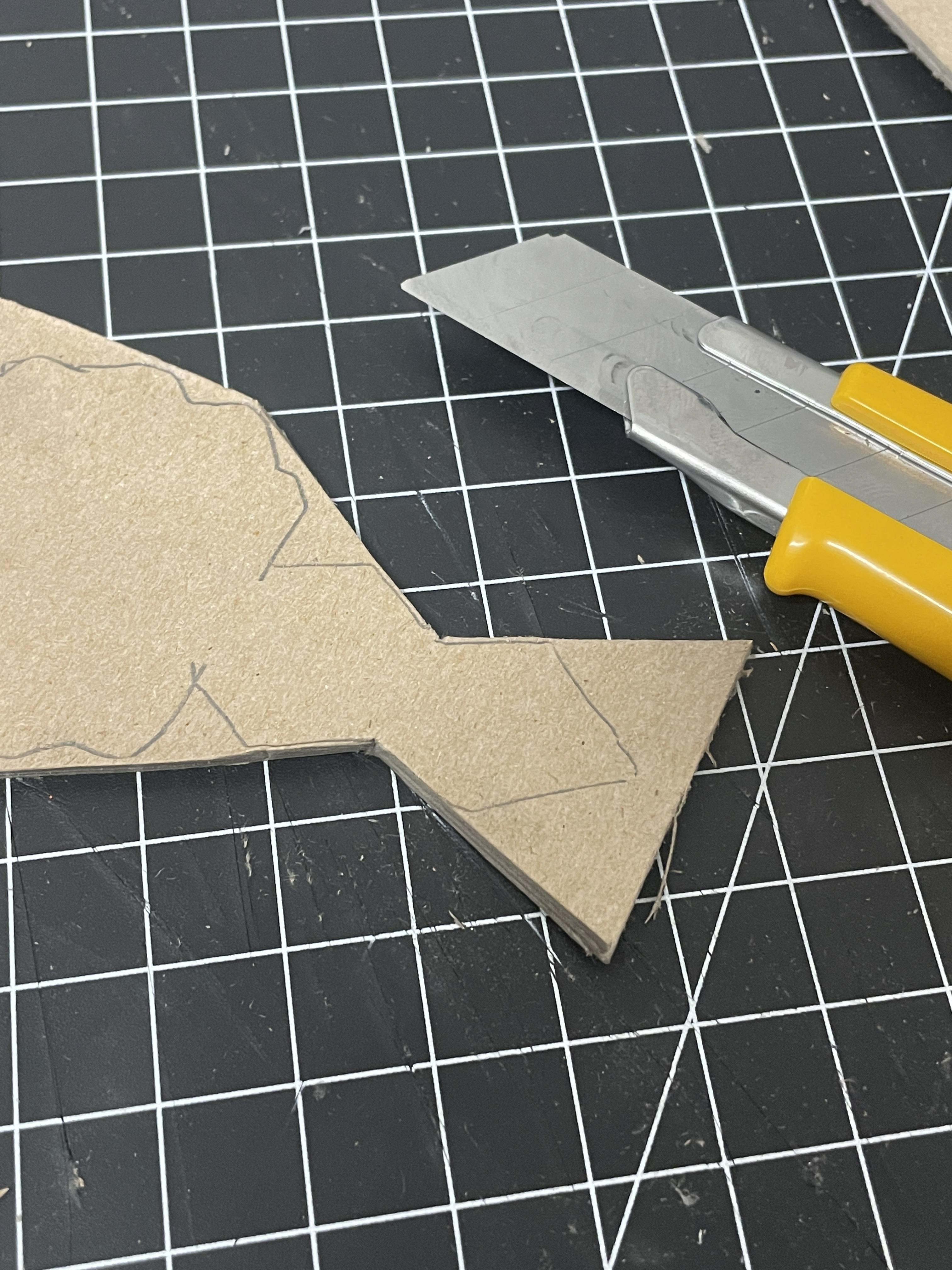

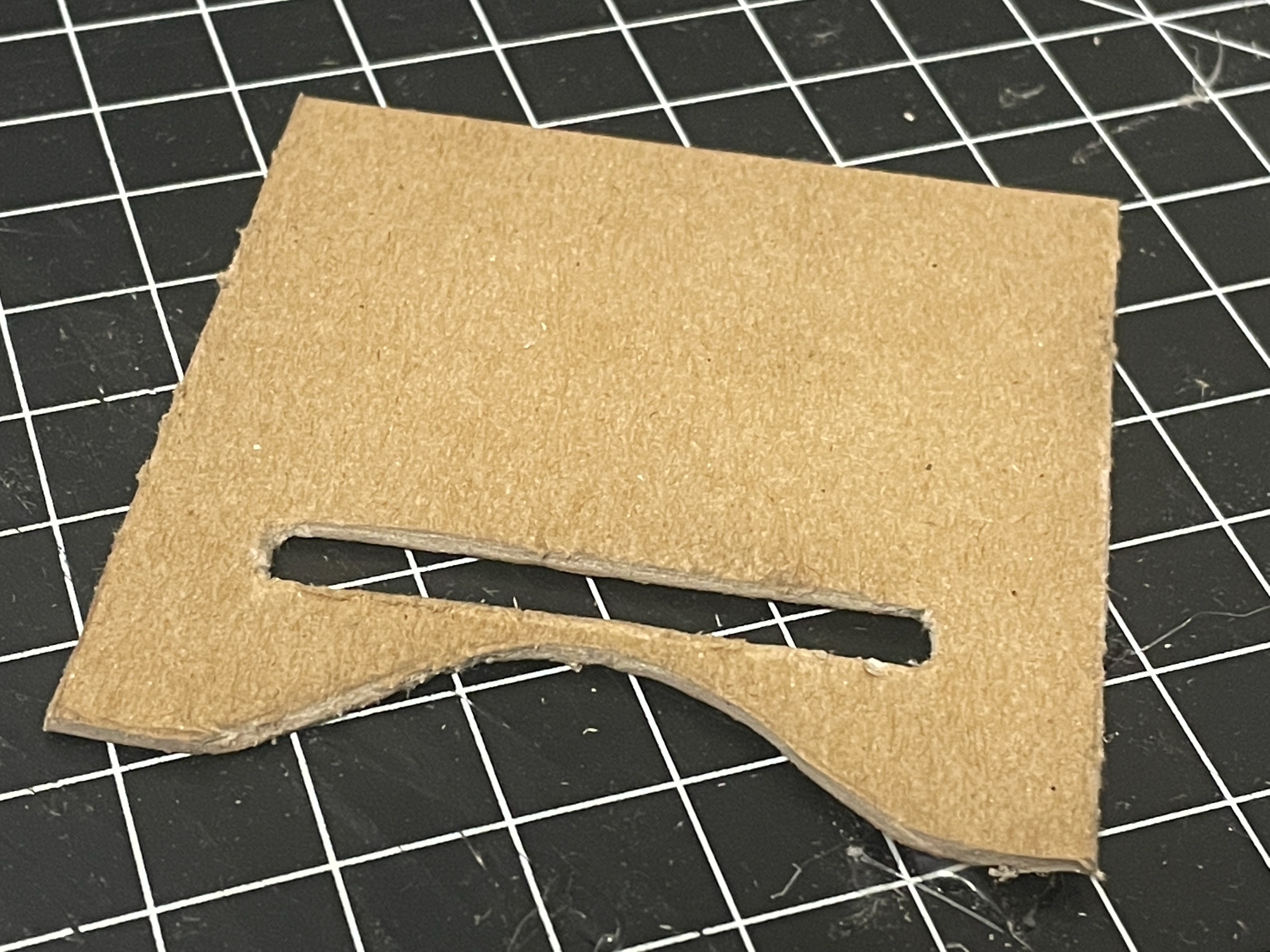

(10) Cutting the bottom section for the same model with the same applied techniques.

(11) Great Result!

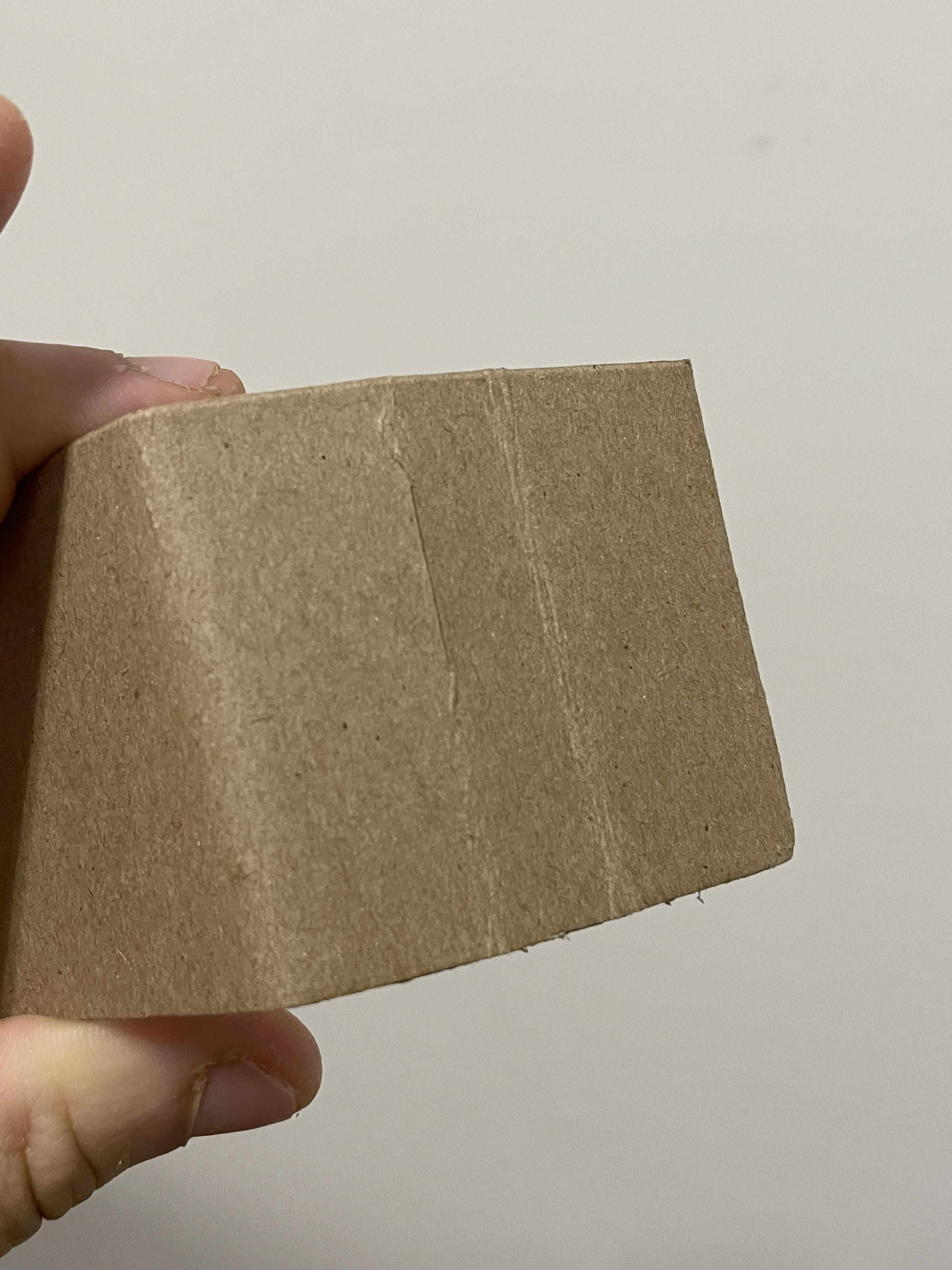

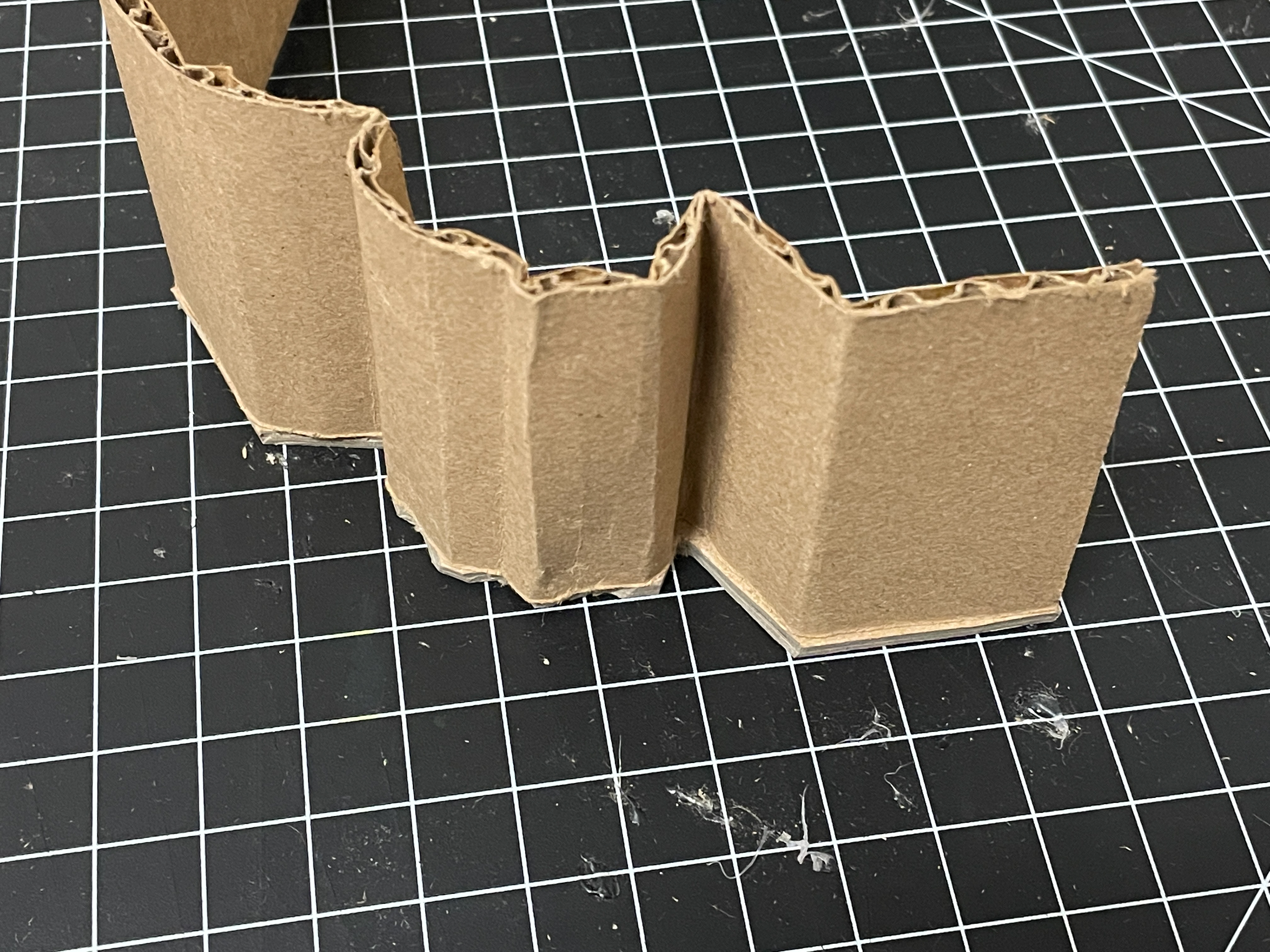

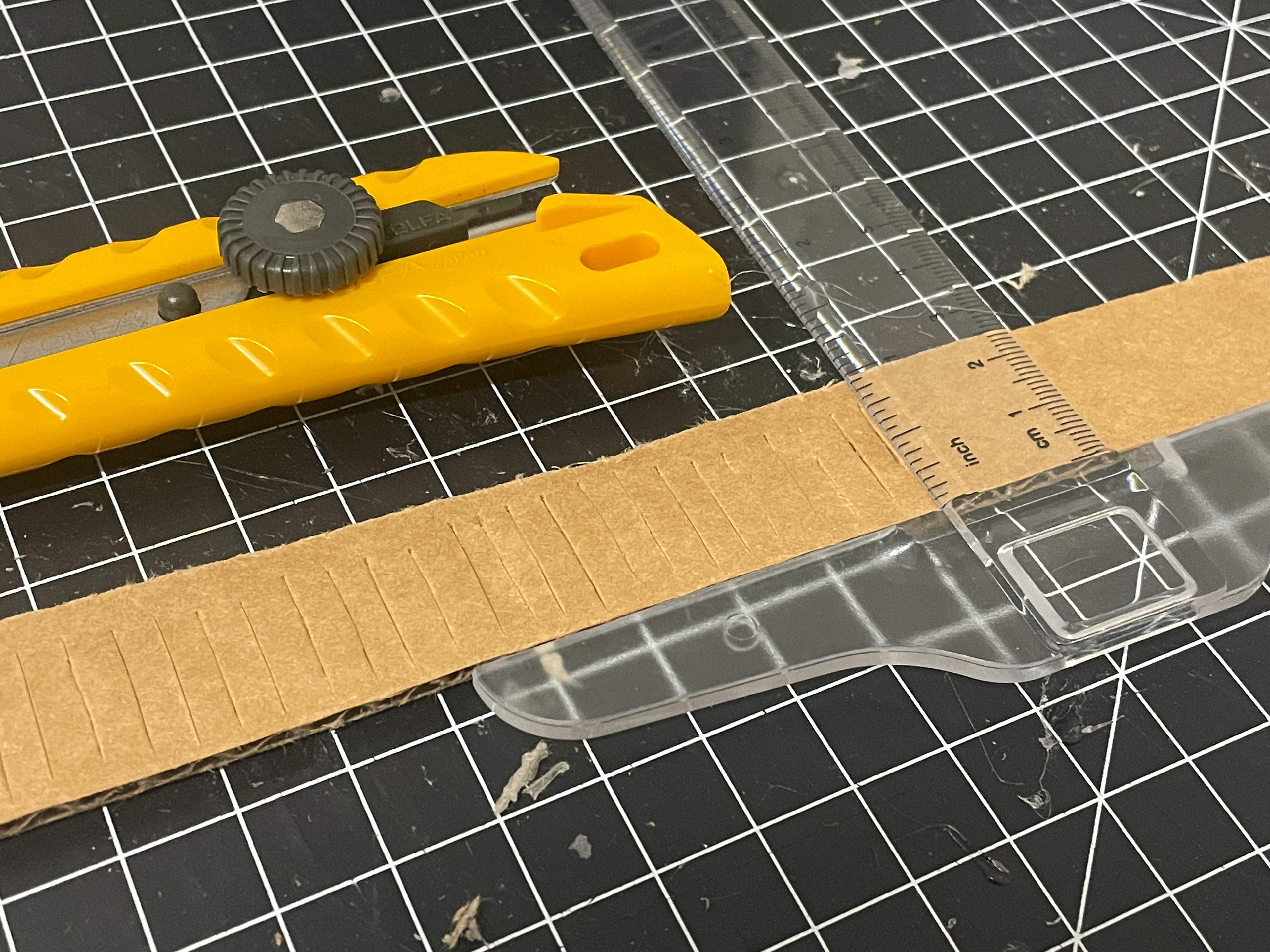

(12) Experimenting with different types of cardboard to find the one that has the least amount of cracks when bent for a higher-fidelity result.

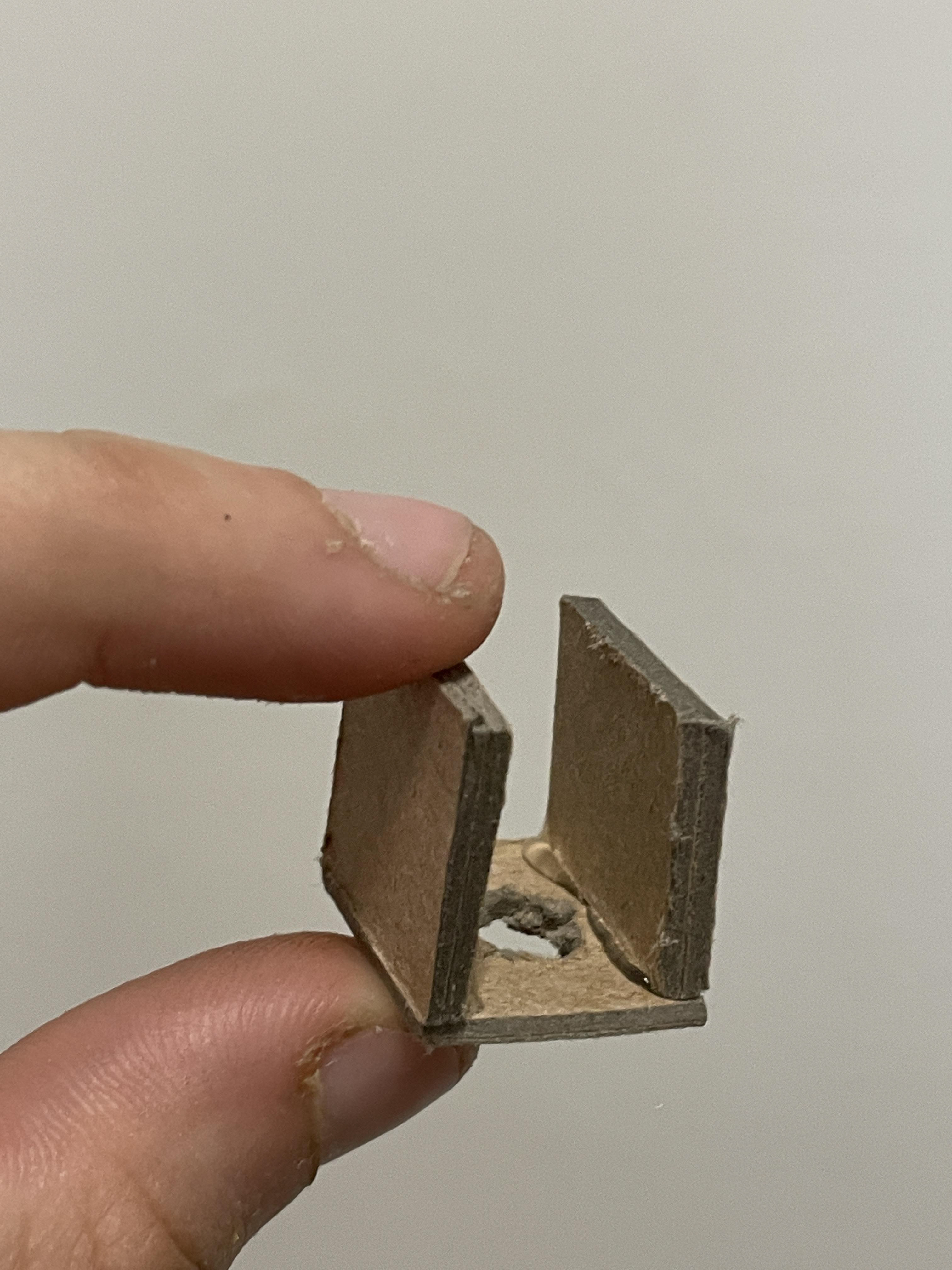

(13) Scoring the cardboard with measured horizontal lines for high precision and great bend.

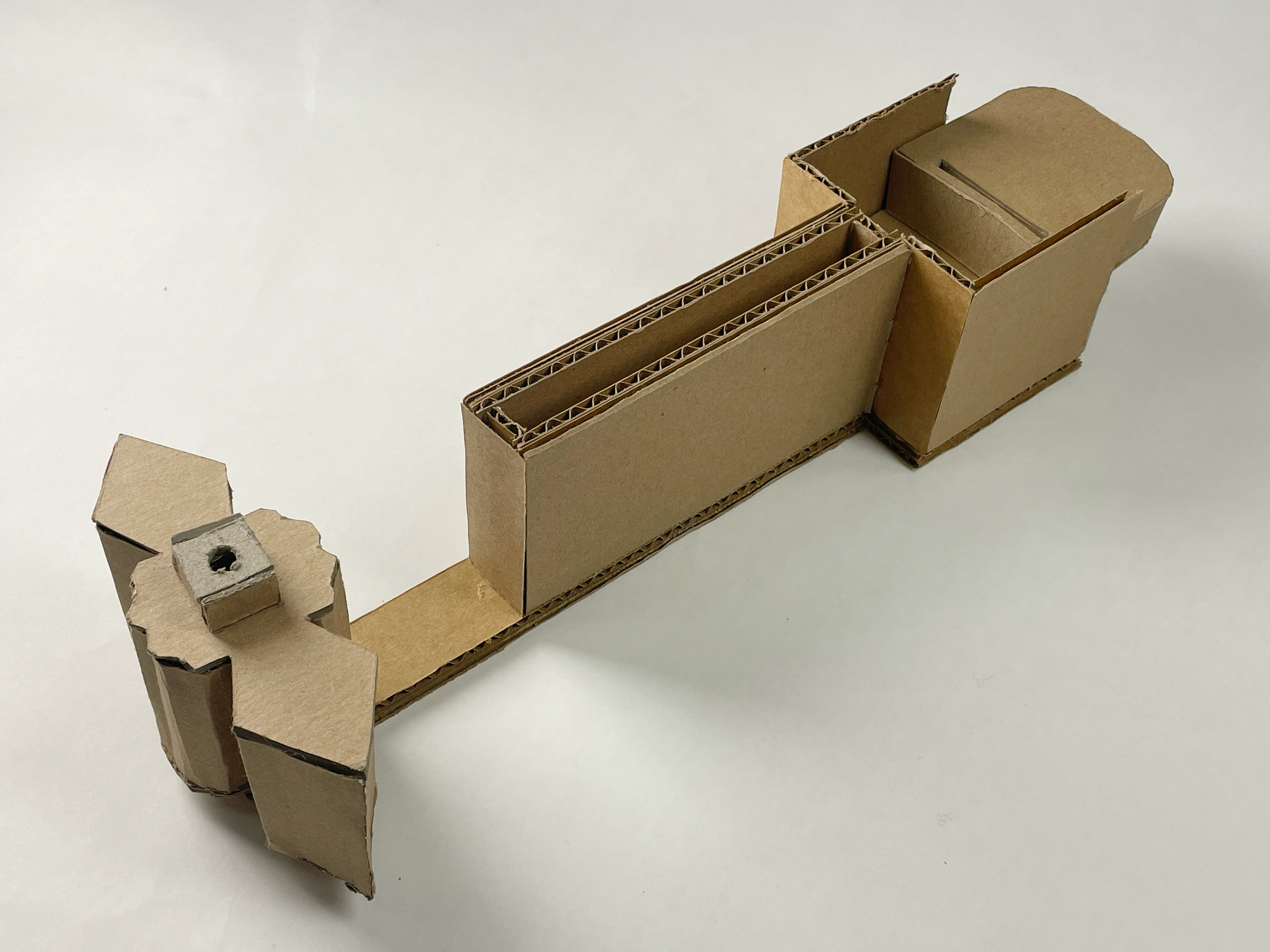

(14) Even though I simplified the model, it was still causing issues due to high complexity and low surface area, so I devised new construction drawings based on this early failure (pivoting).

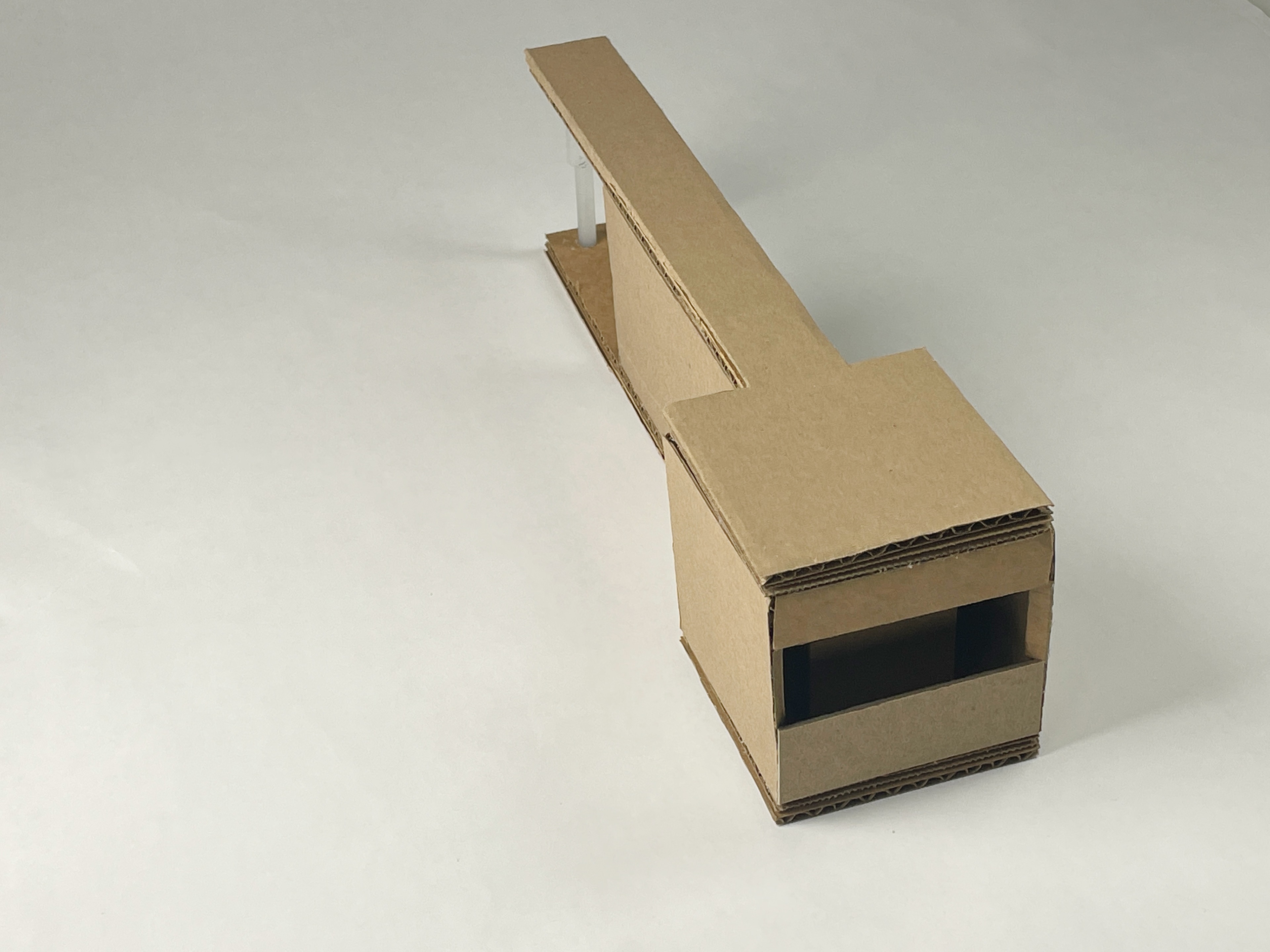

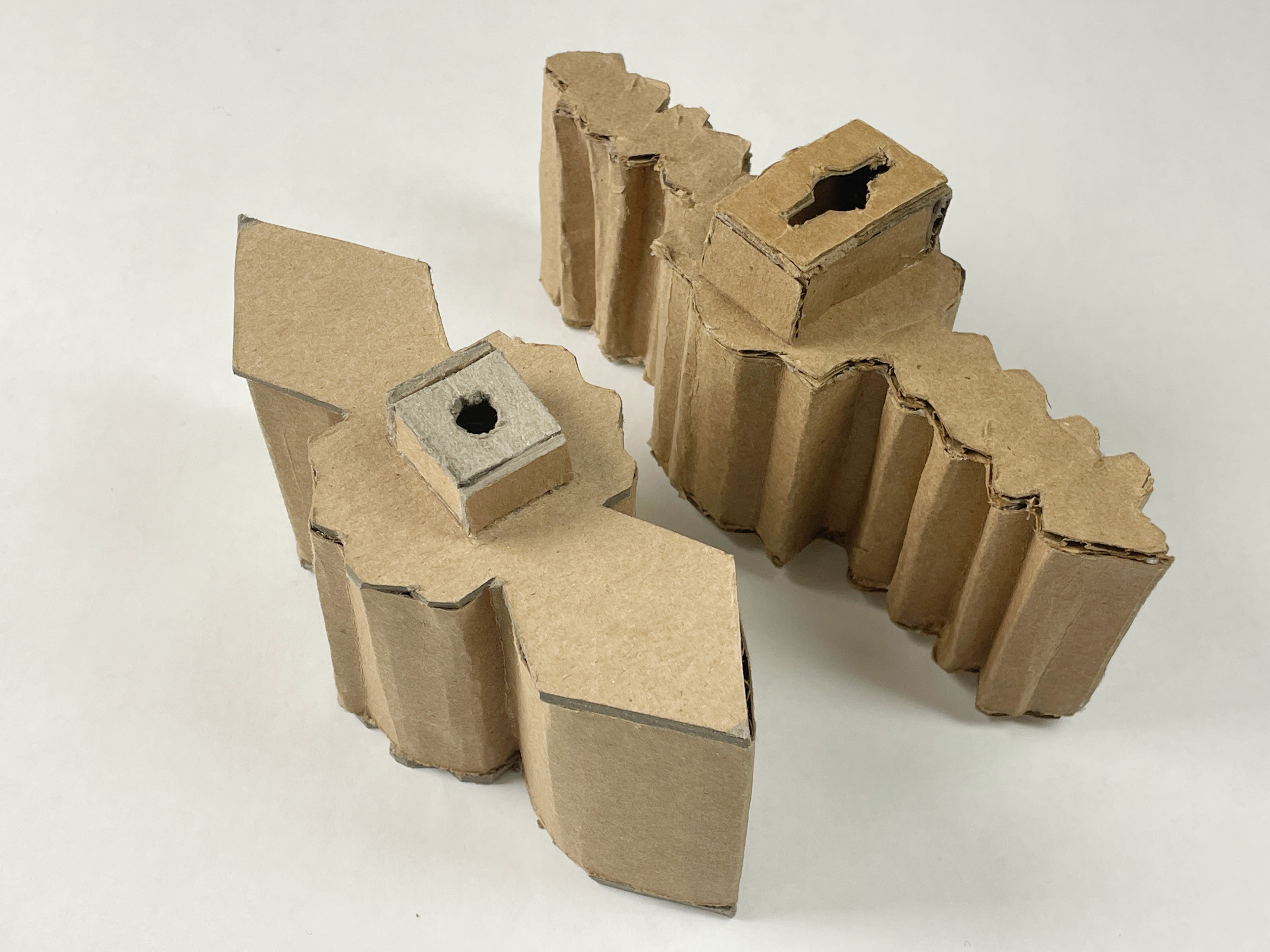

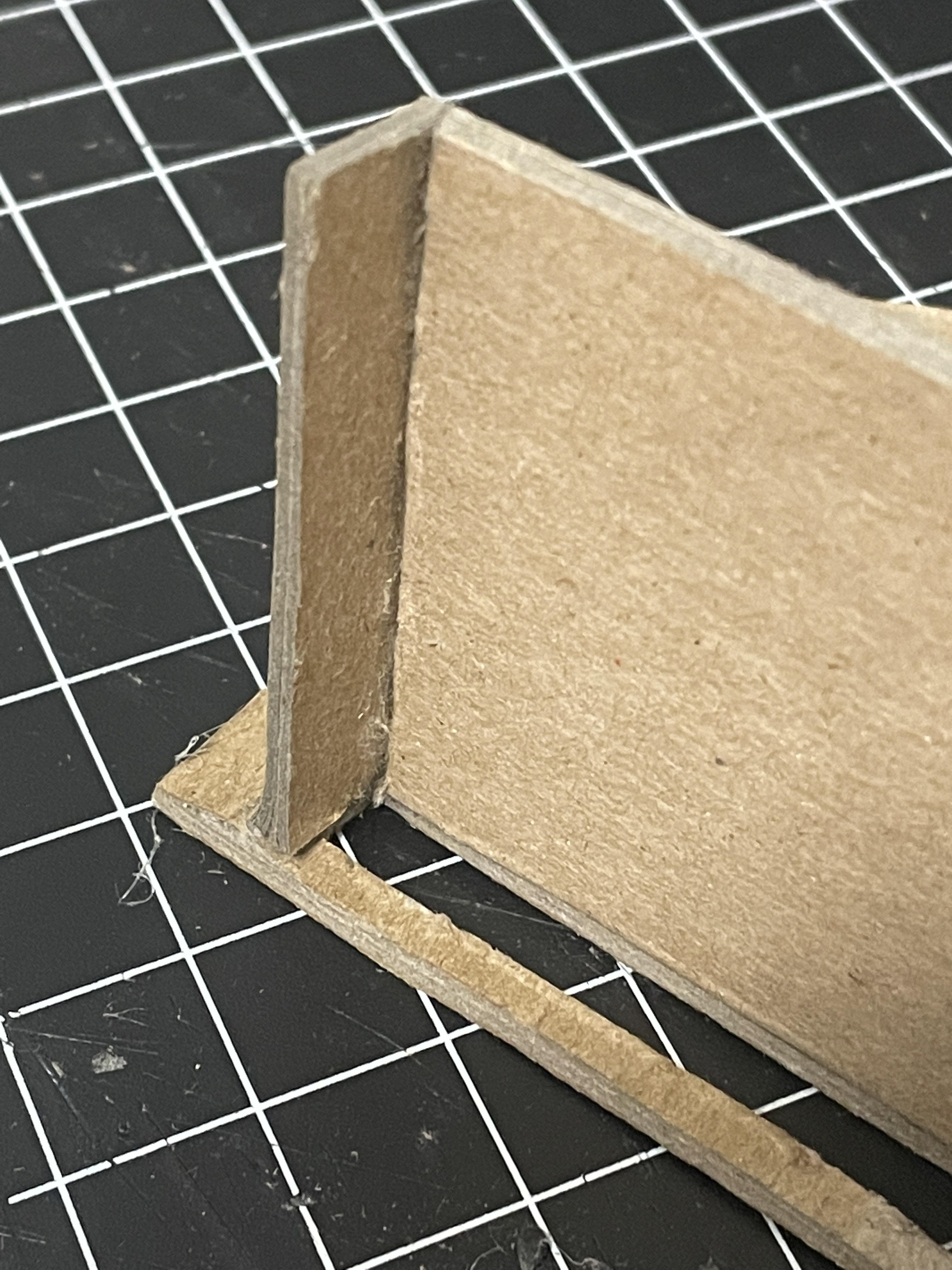

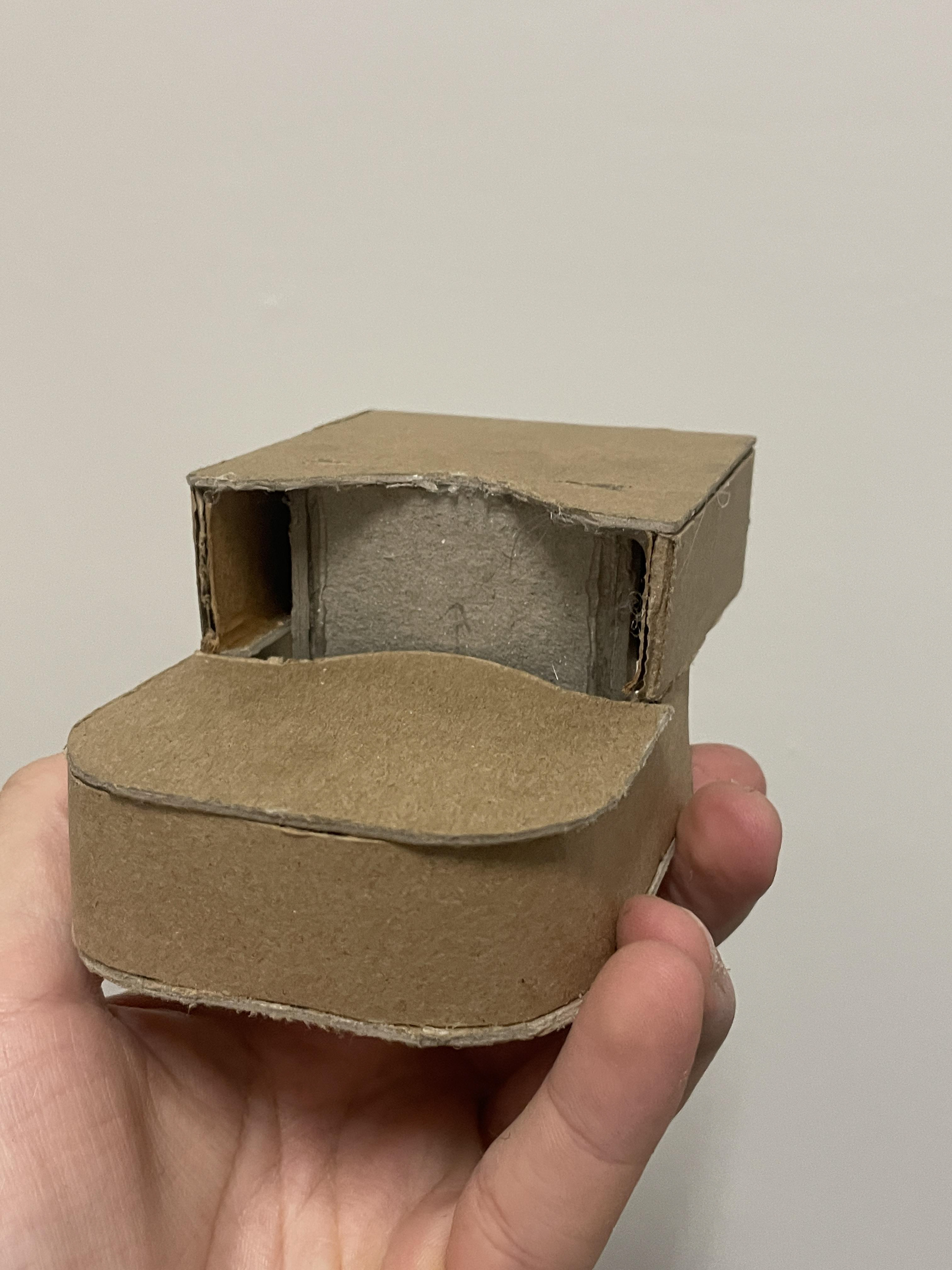

(15) I did the same process as for the original profiles, and then attached the parts together by gluing corners inside so the glue is not visible when seen from the outside*.

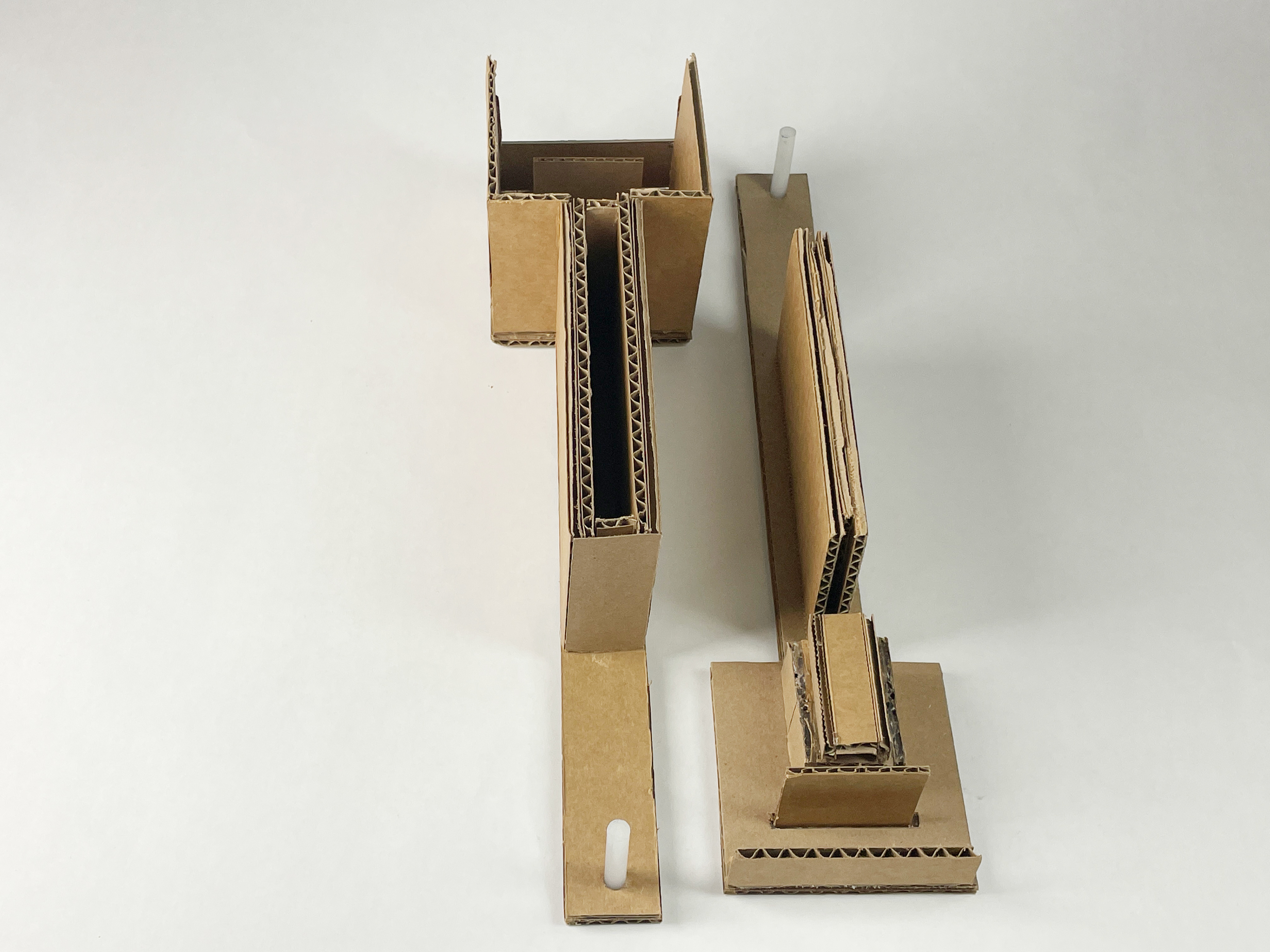

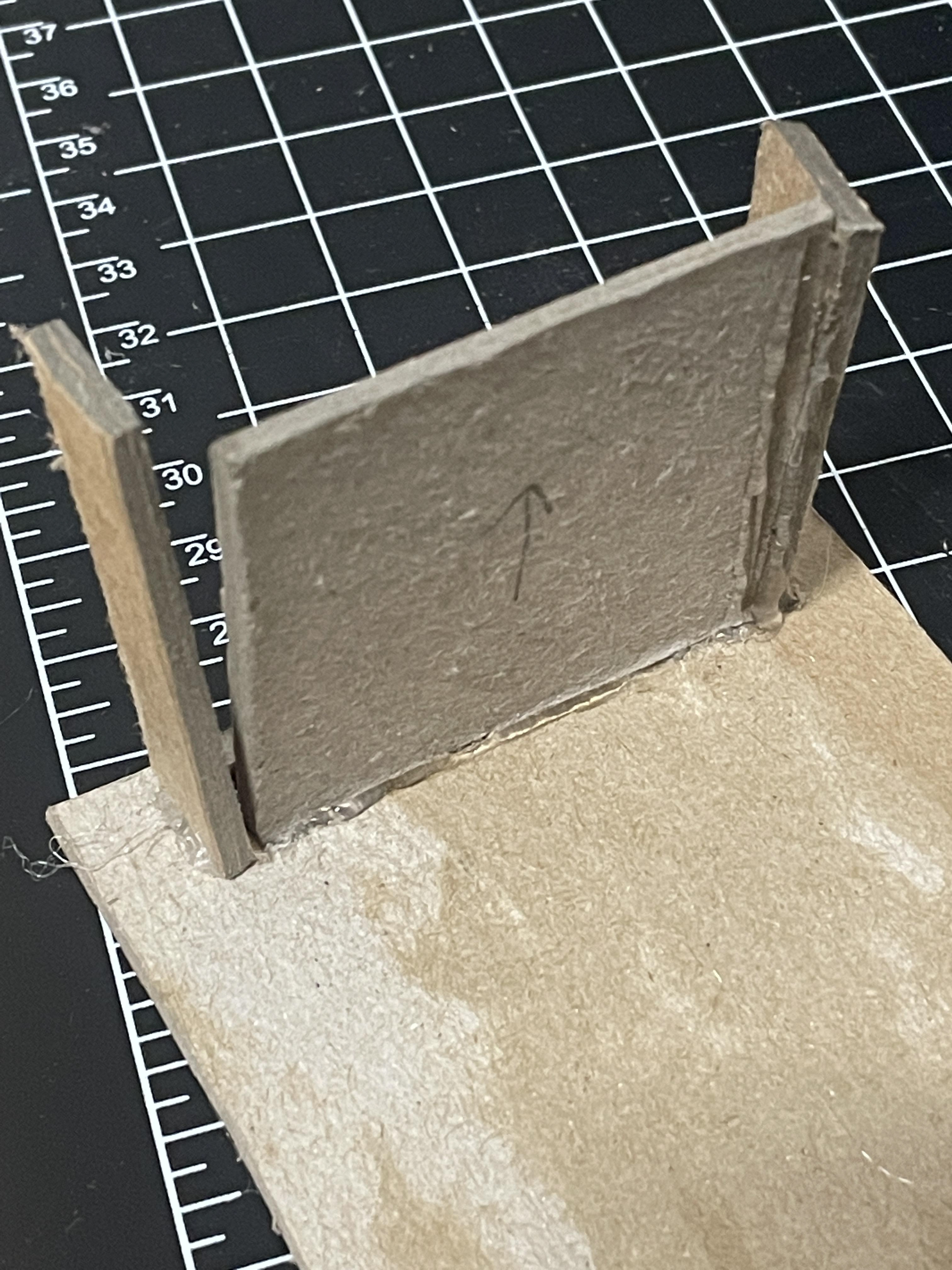

(16) Testing axial cylinder mechanism with glued together parts…

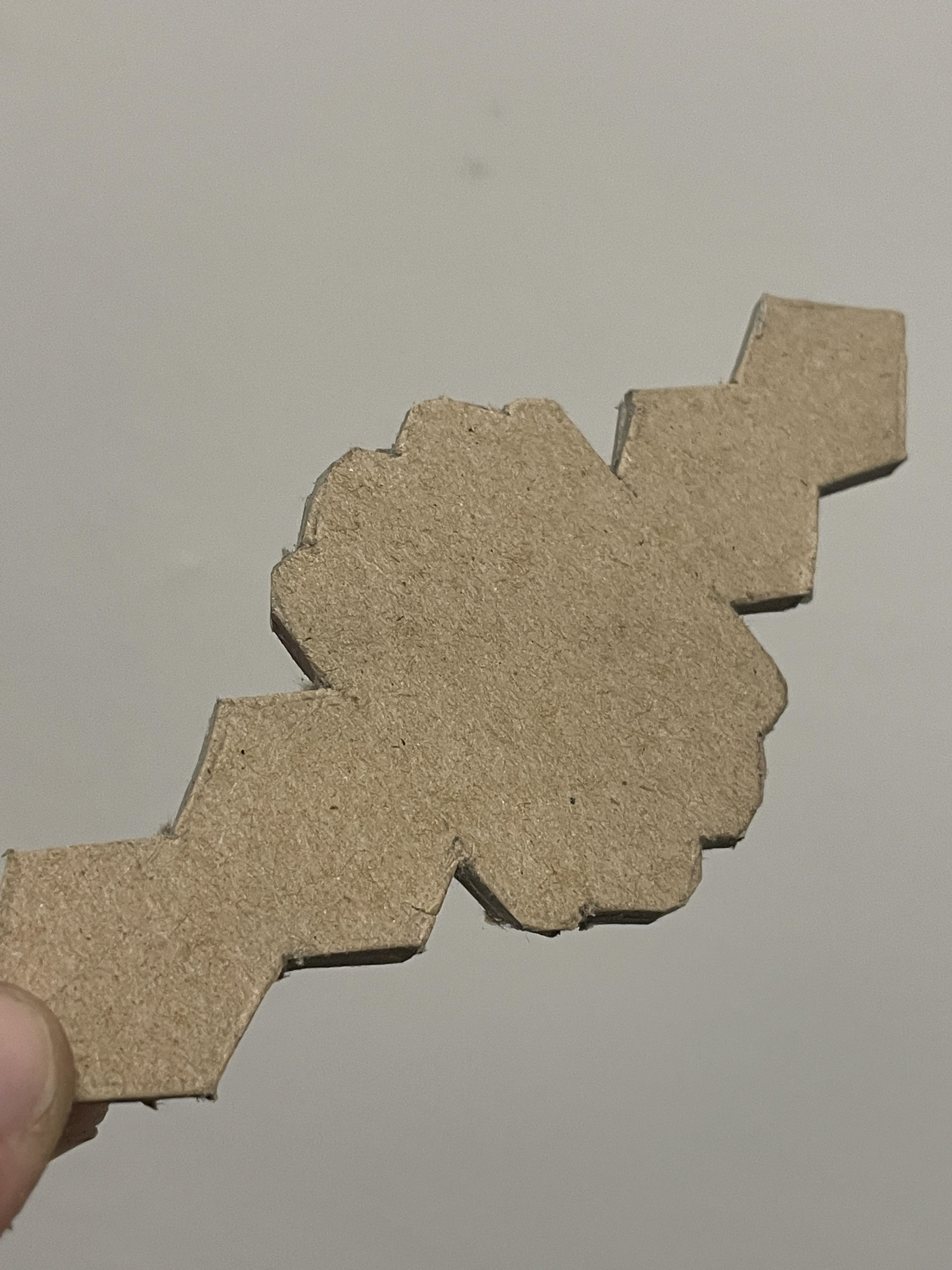

(17) Final part… Making the nice key-inspired layer at top of the shape.

(18) Looking great! The second object is a lower-fidelity comparison.

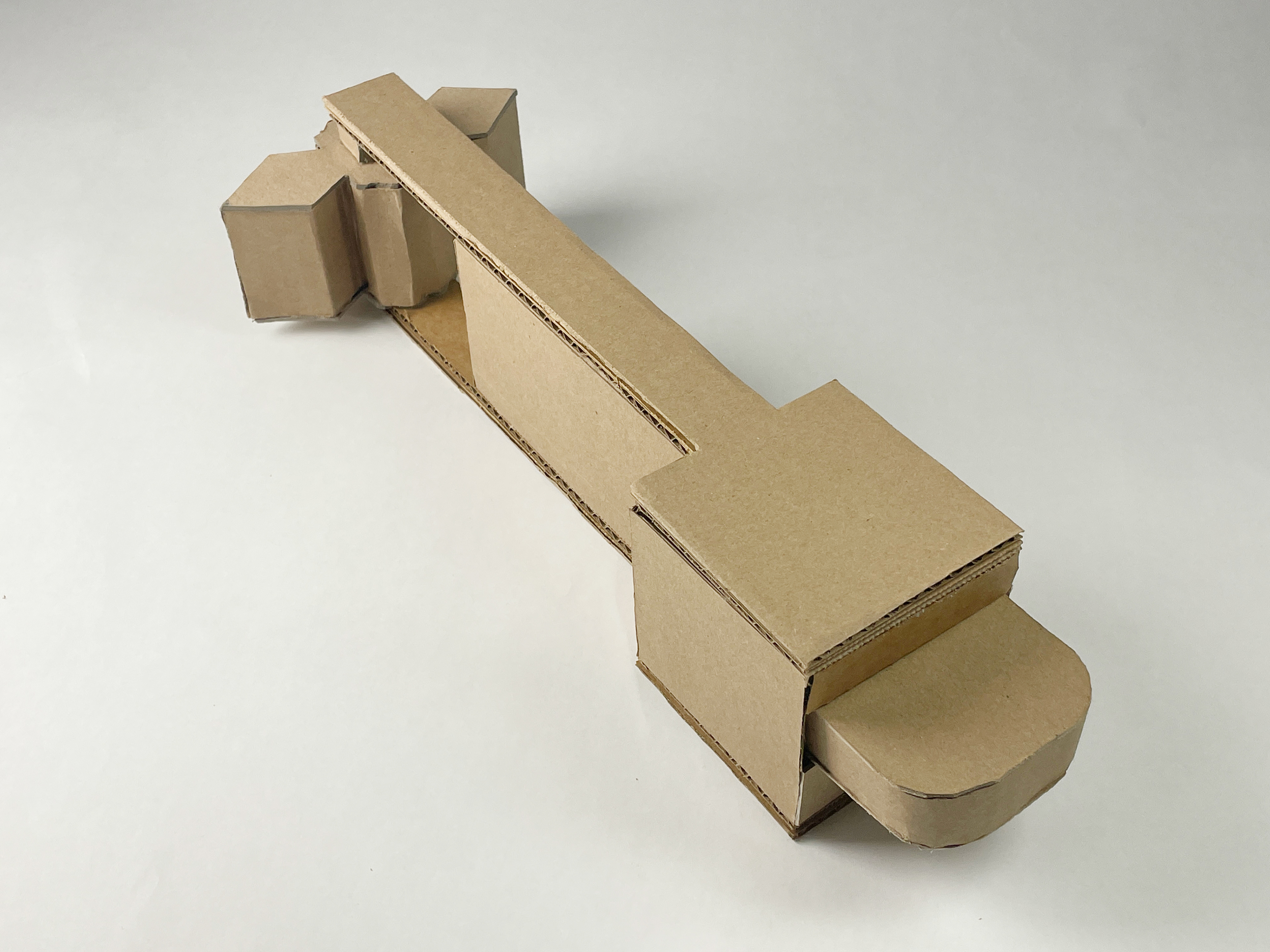

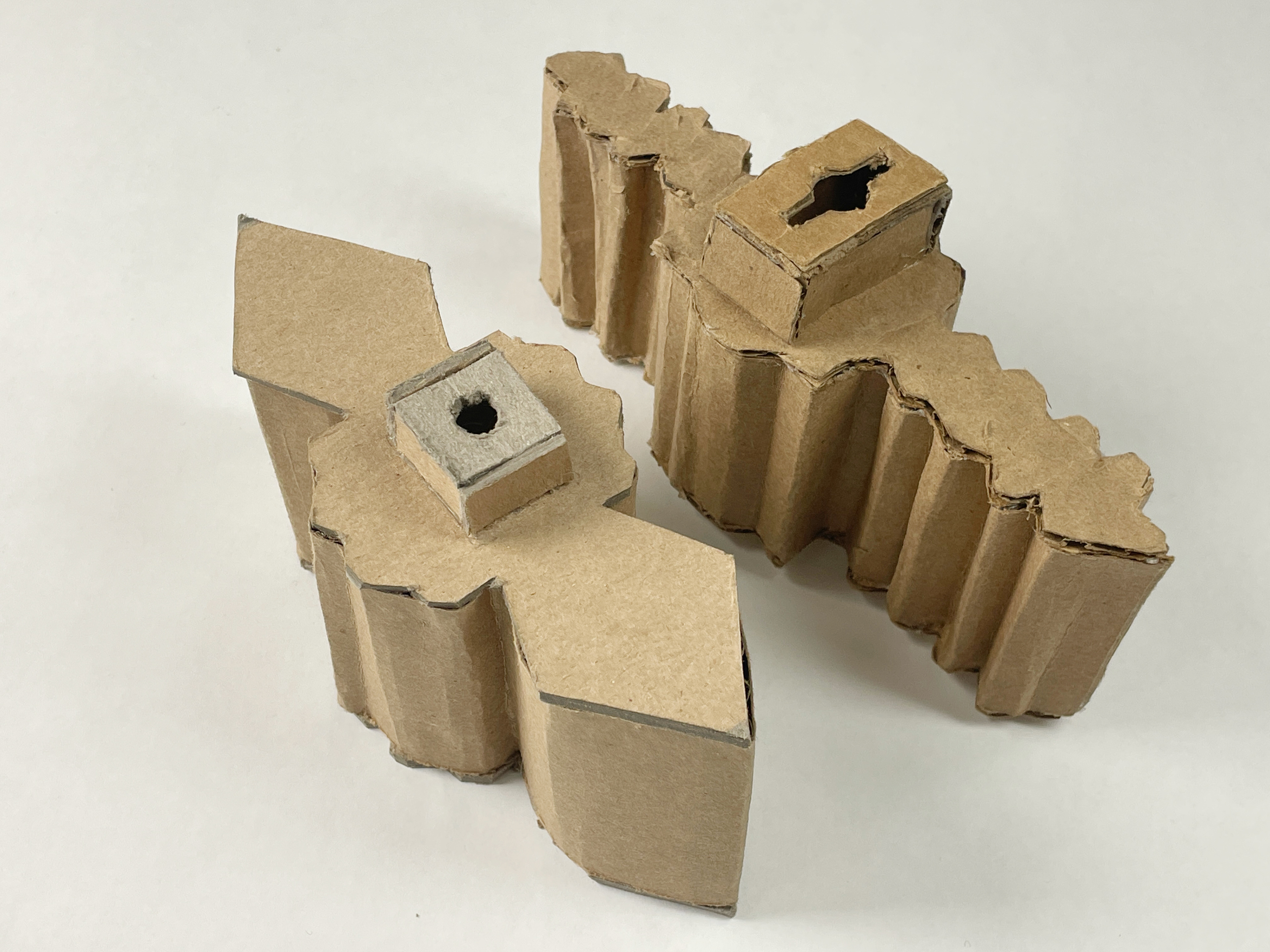

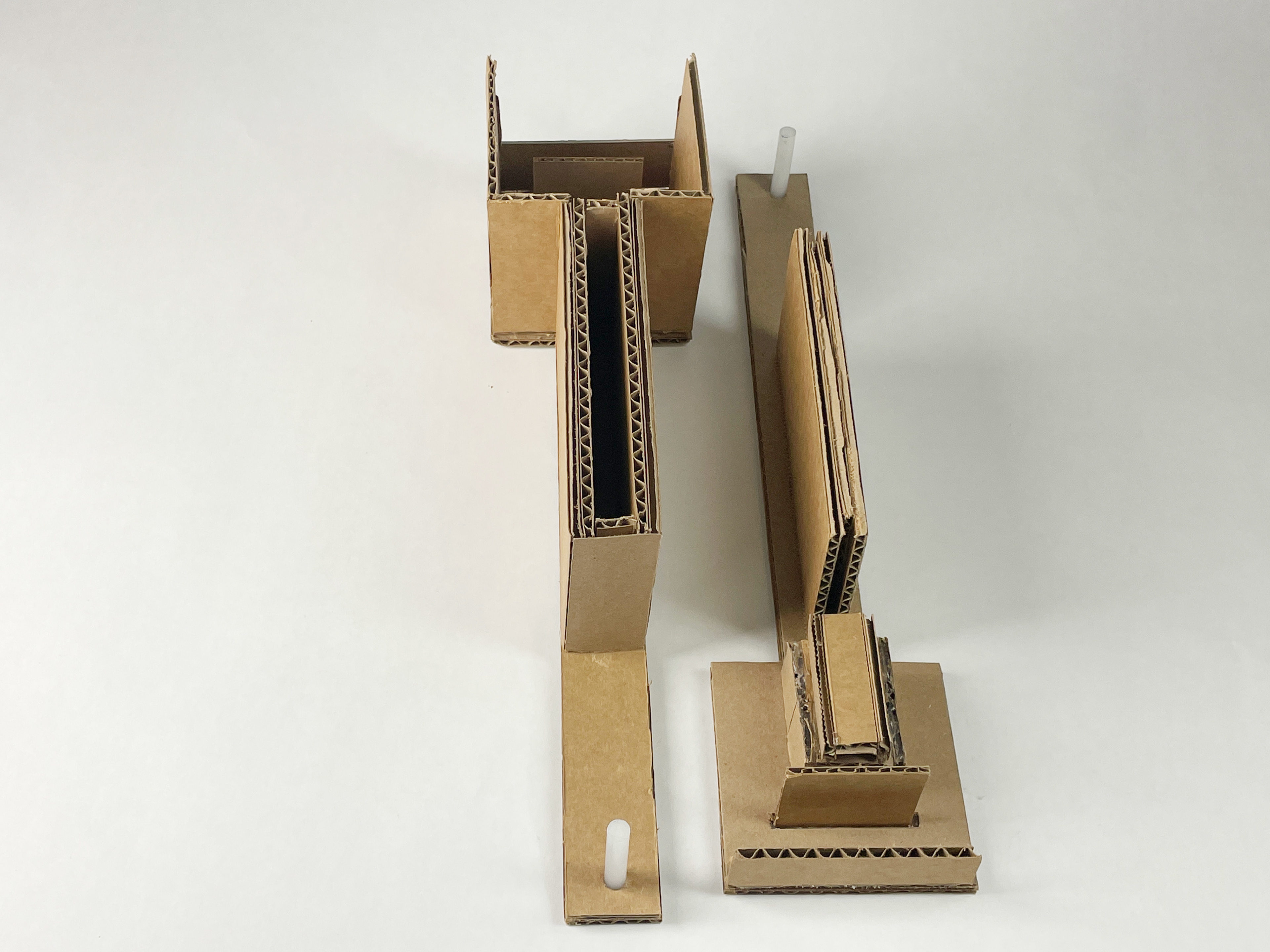

Second High-Fidelity Model

(1) Using construction drawings for precise measurements.

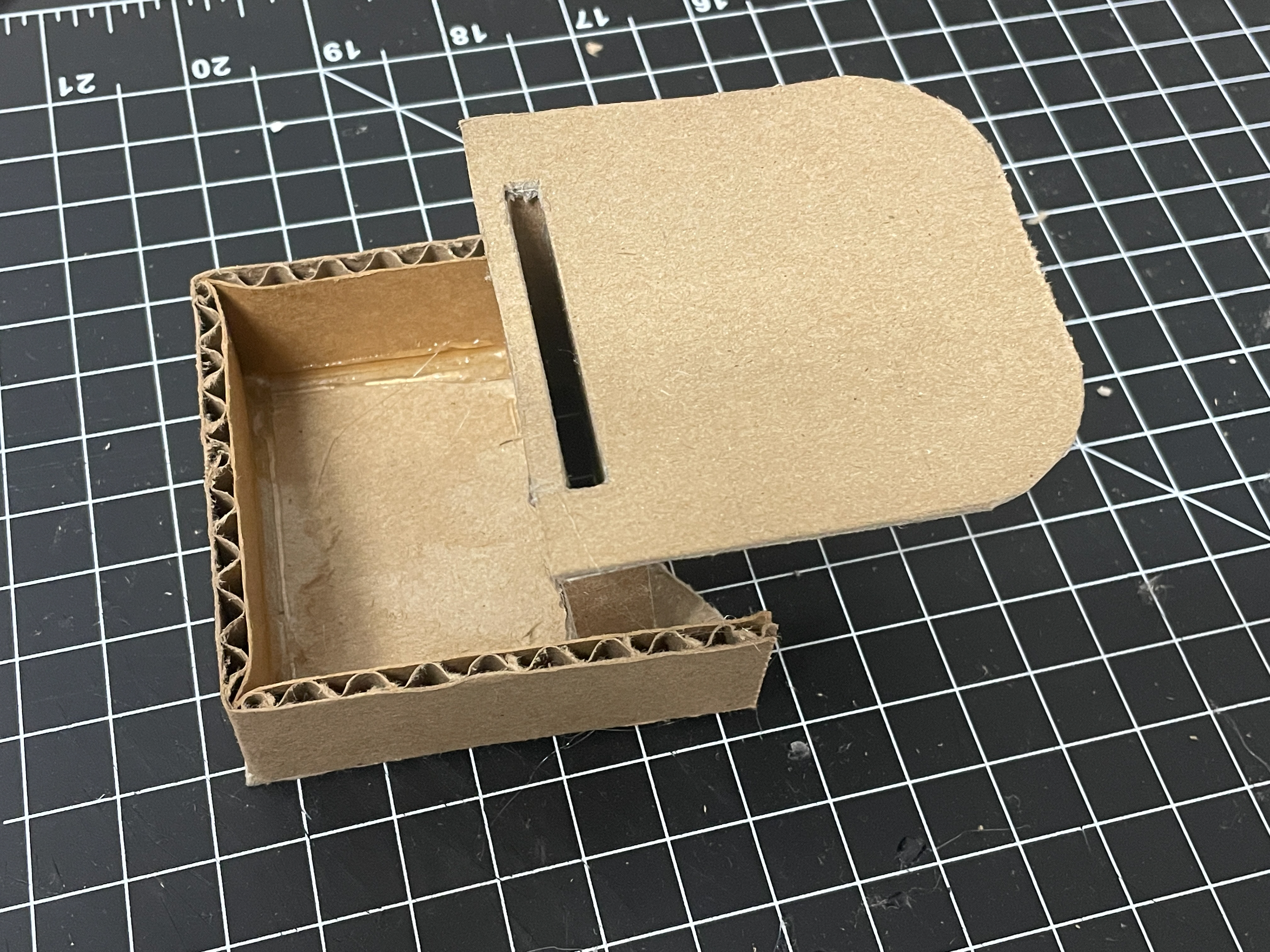

(2) Cutting parts of the model…

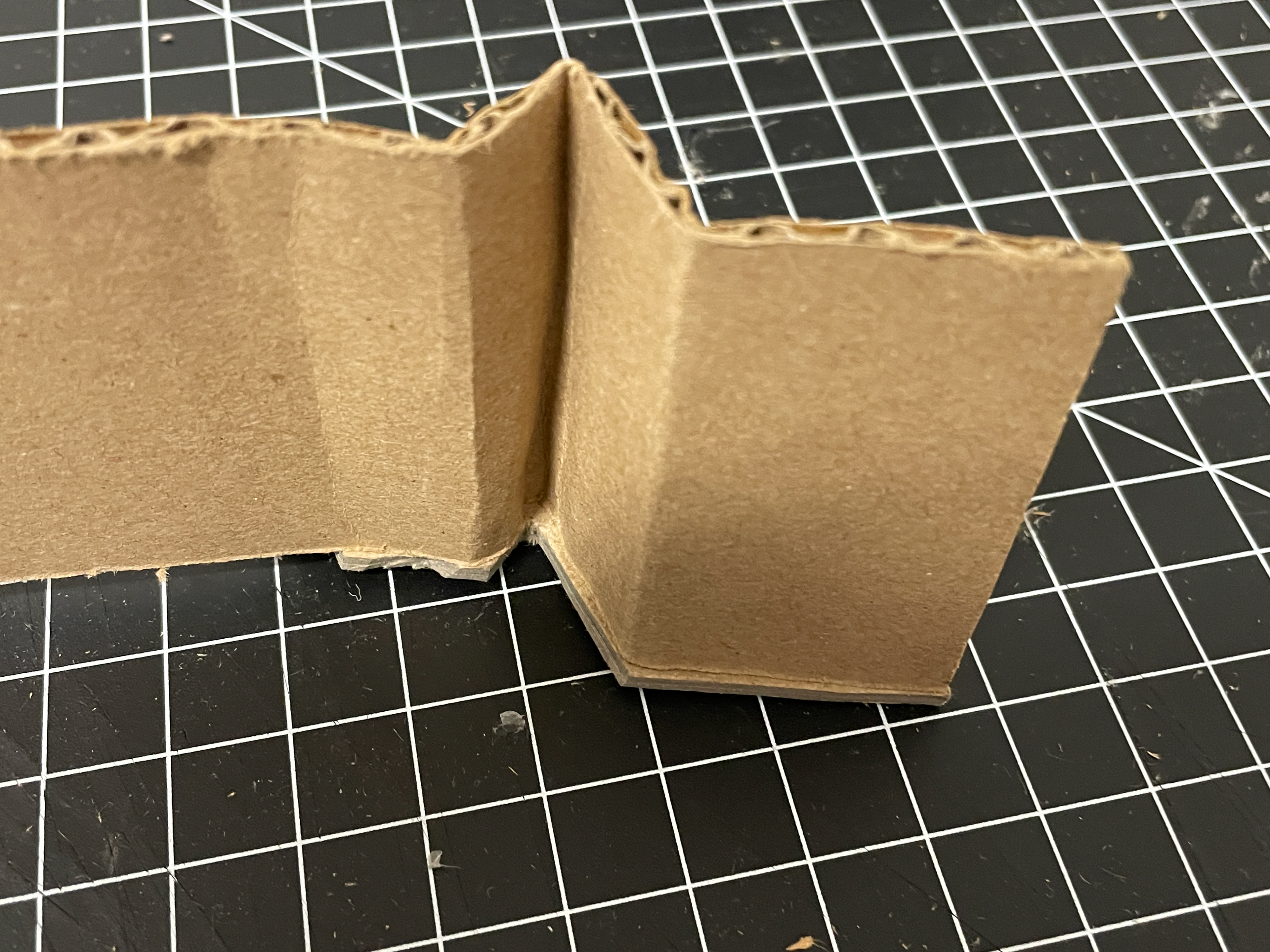

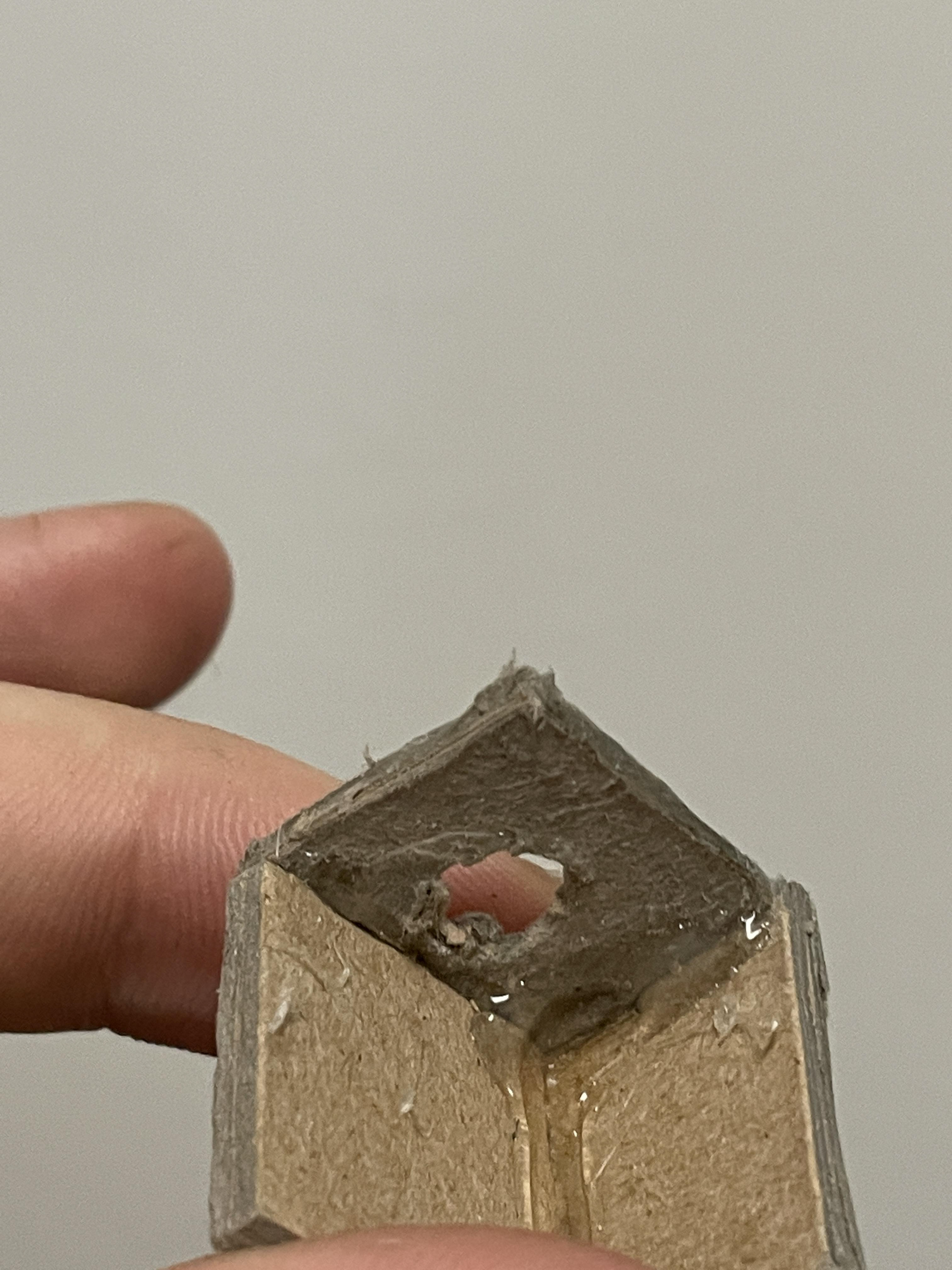

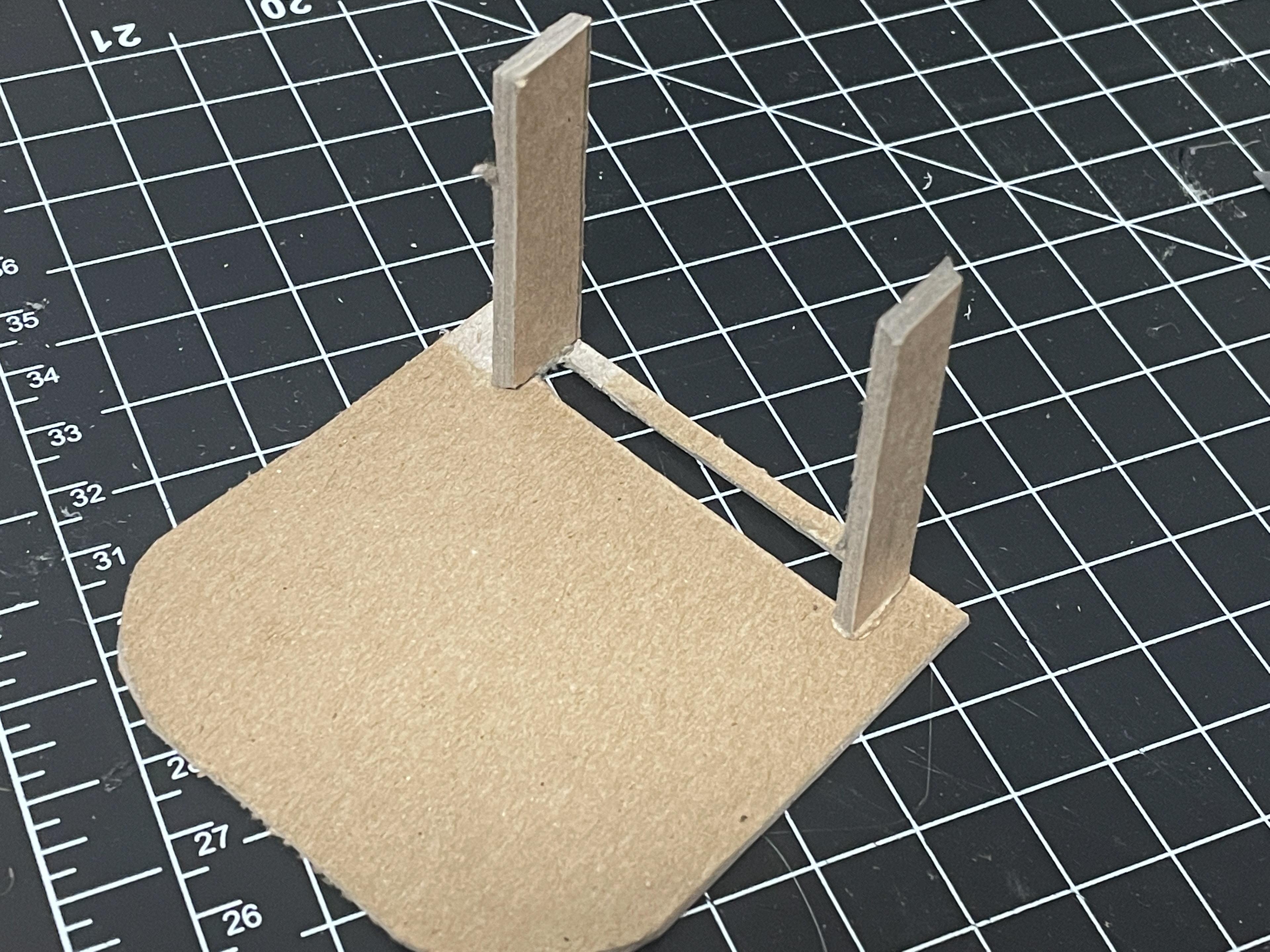

(3) Shifting the order of operations and process build strategy by making the inner hole mechanism flush and flat with a newly developed method: making a rectangular structure with flat walls that make it smooth and clean.

(4) Sketch of the new mechanism

(5) Gluing together structure walls (order of operations).

(6) Final sections to glue together…

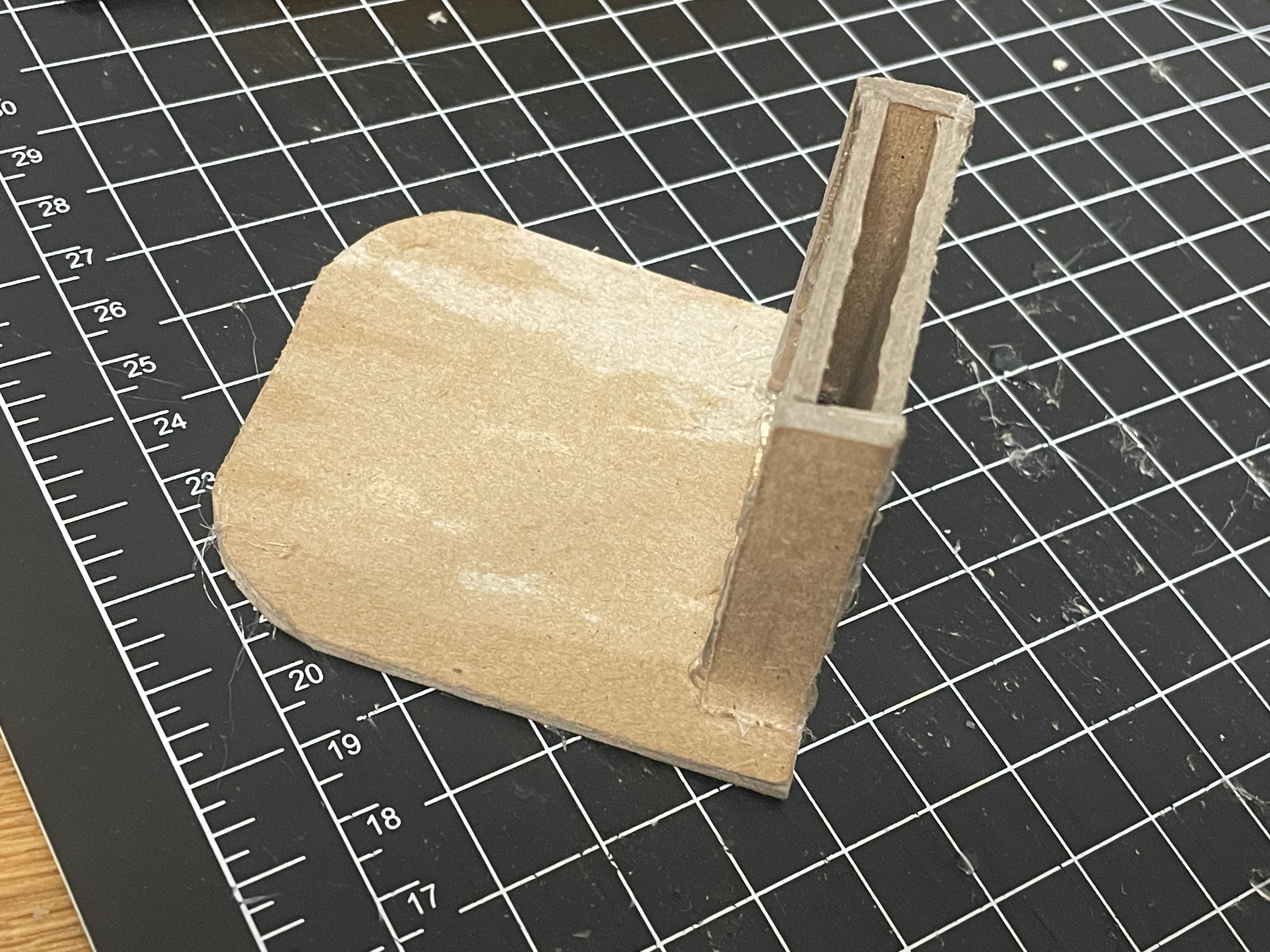

(7) Final Model!

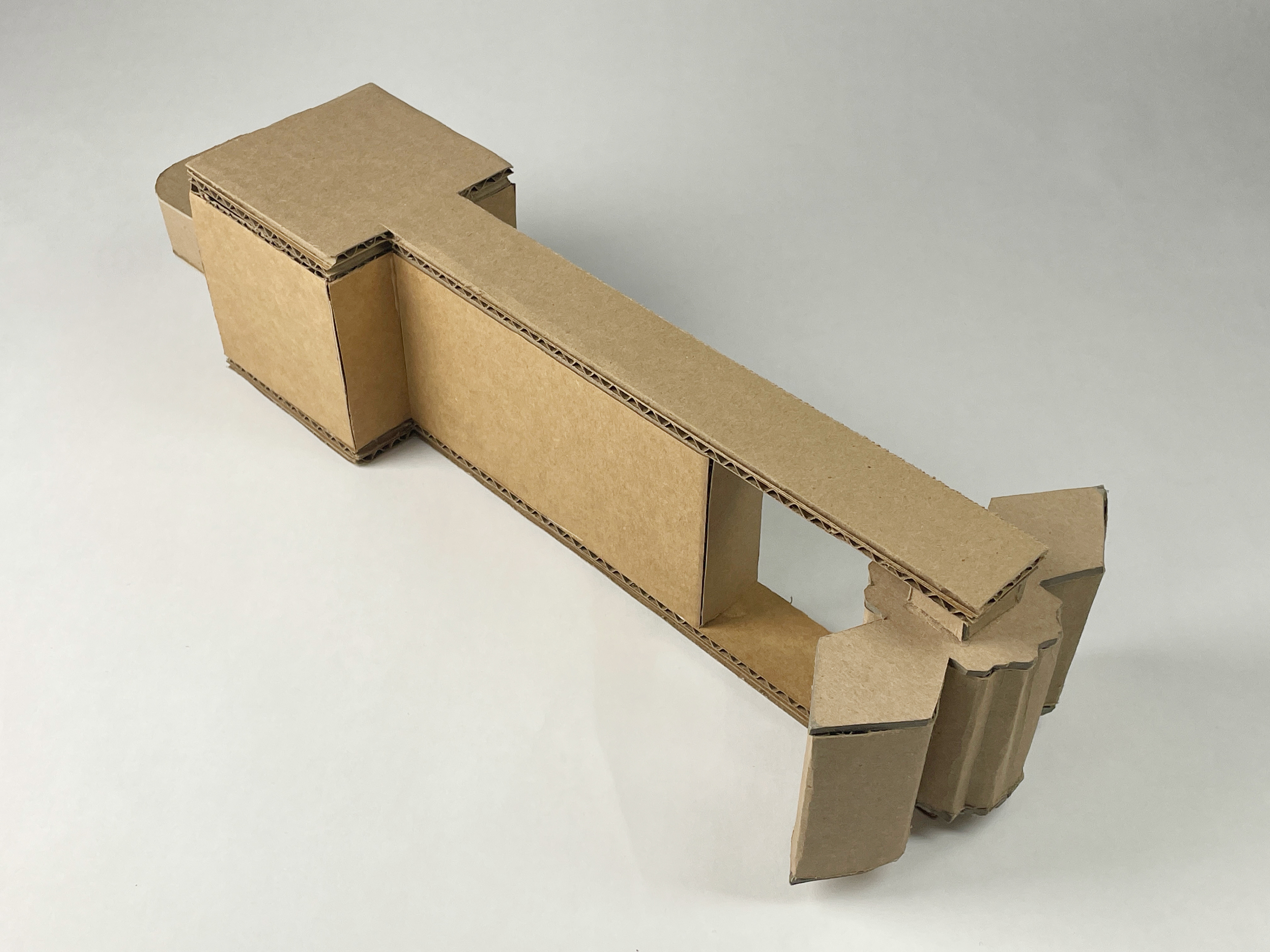

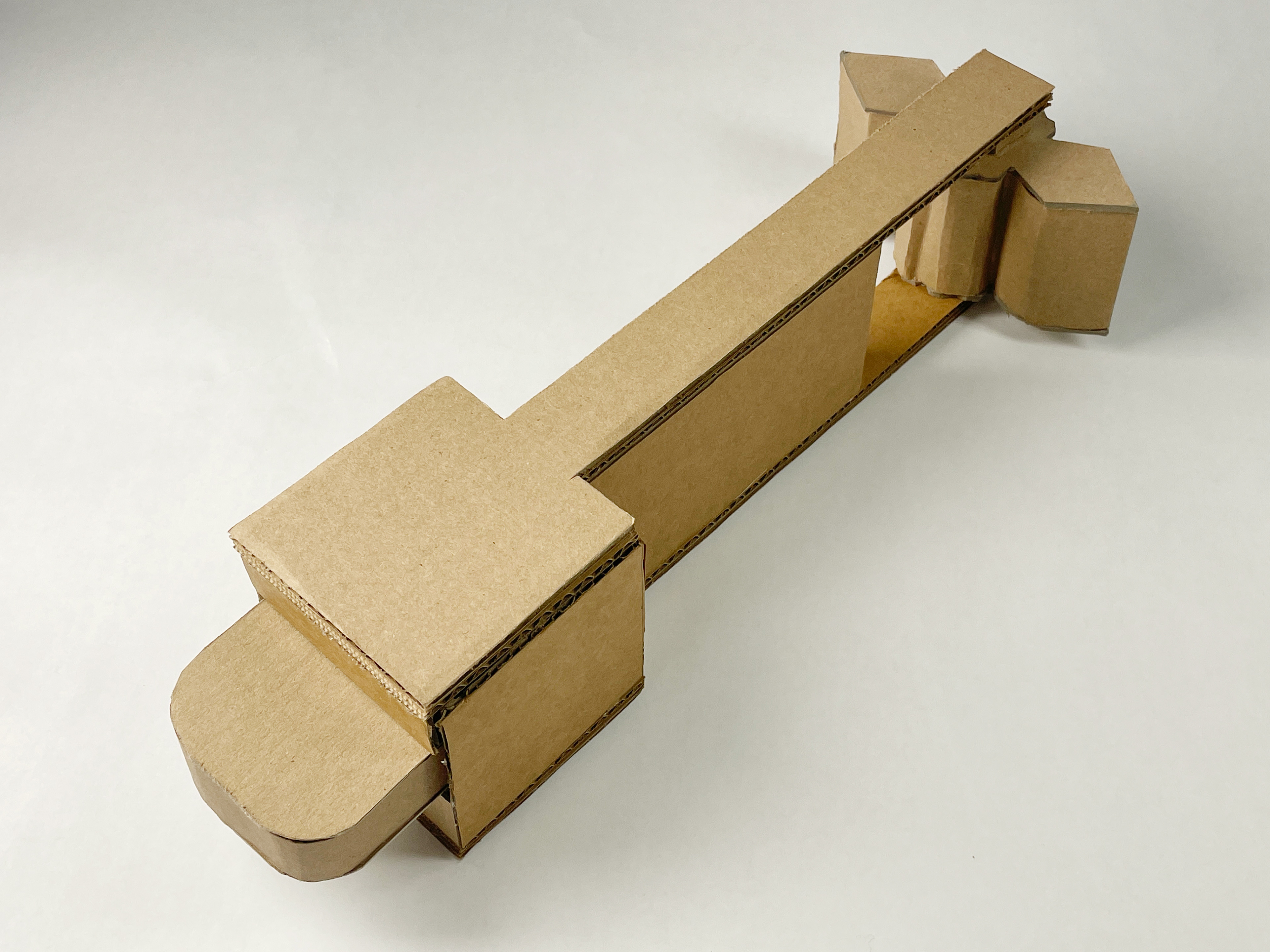

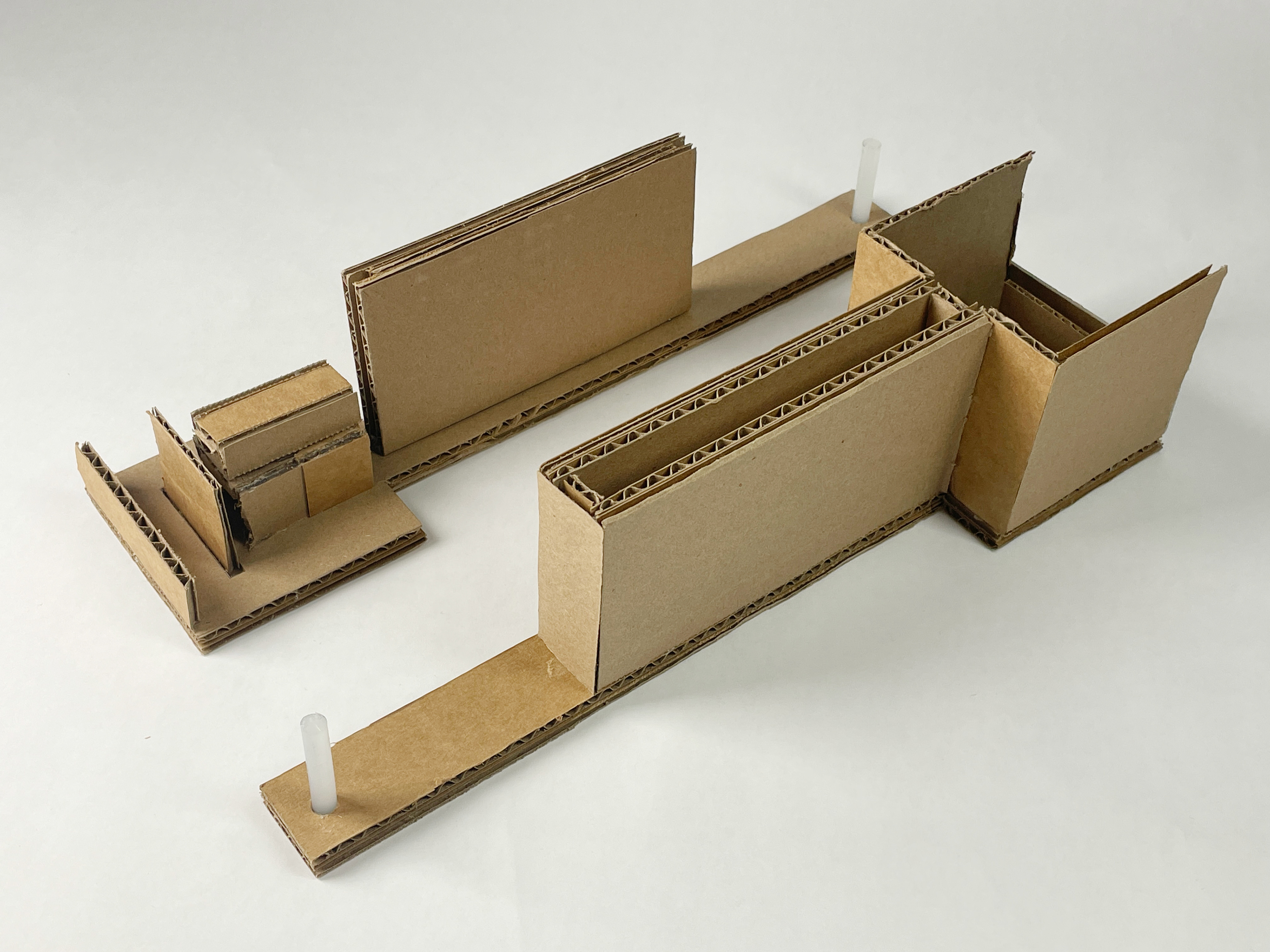

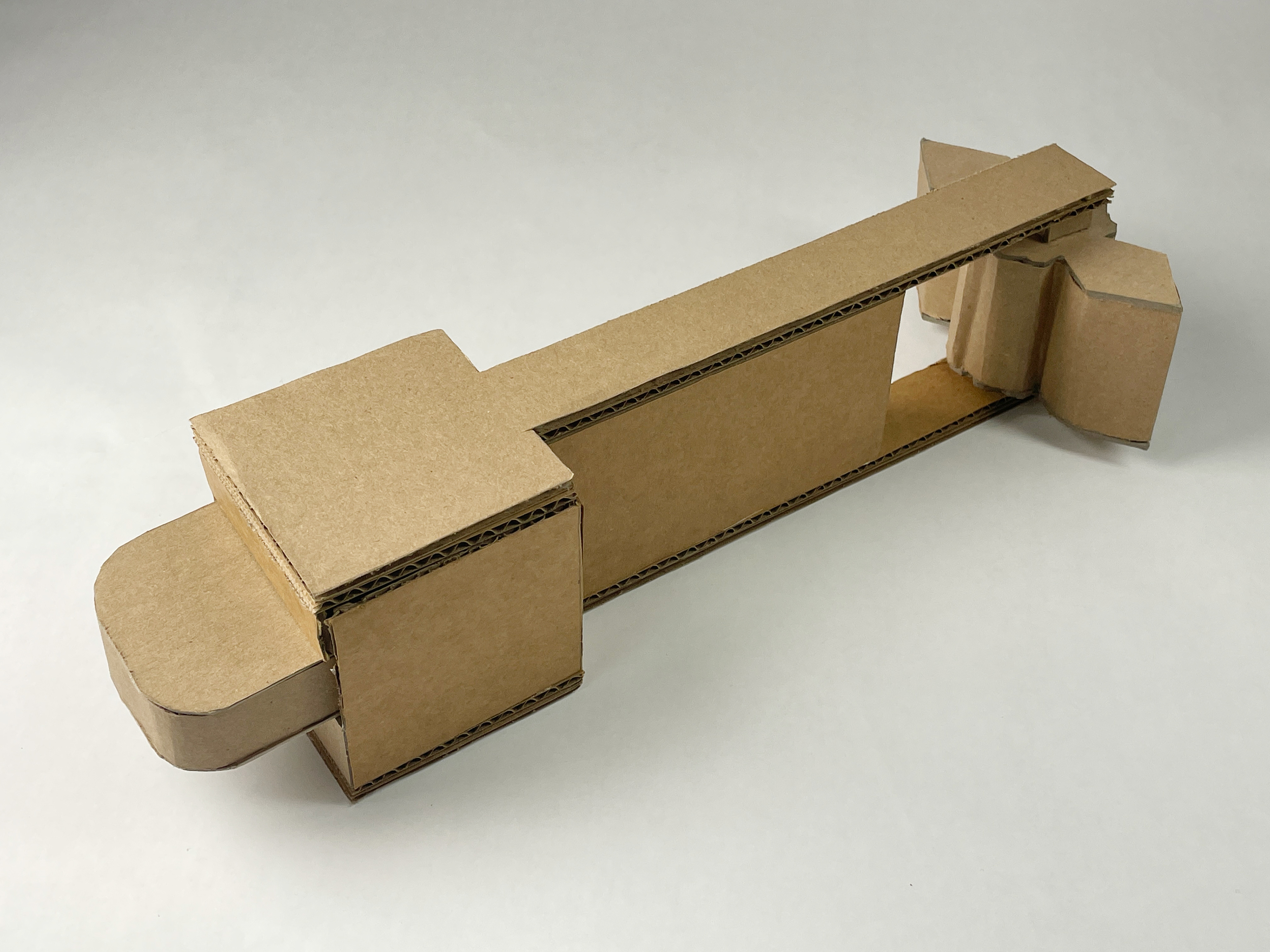

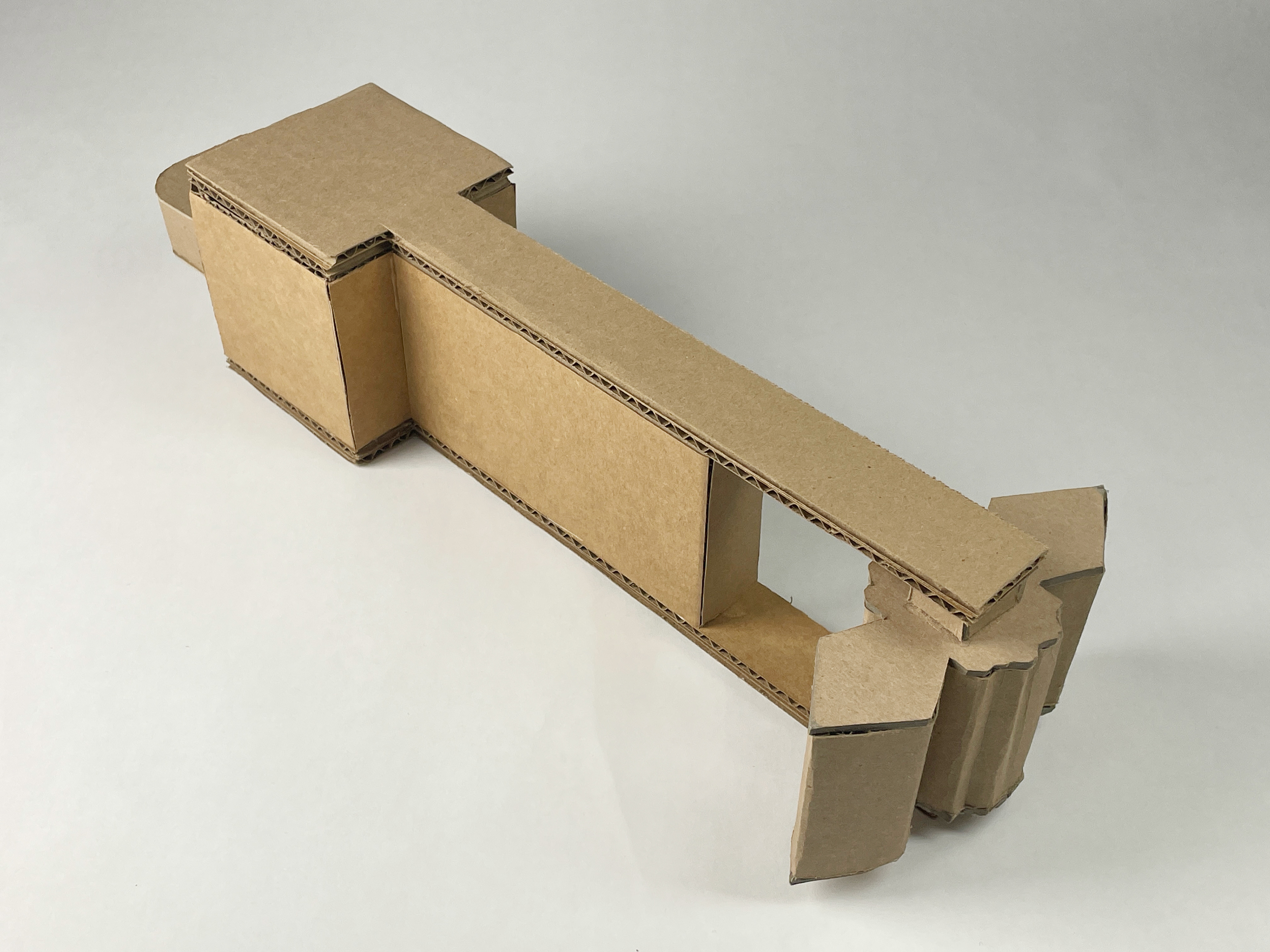

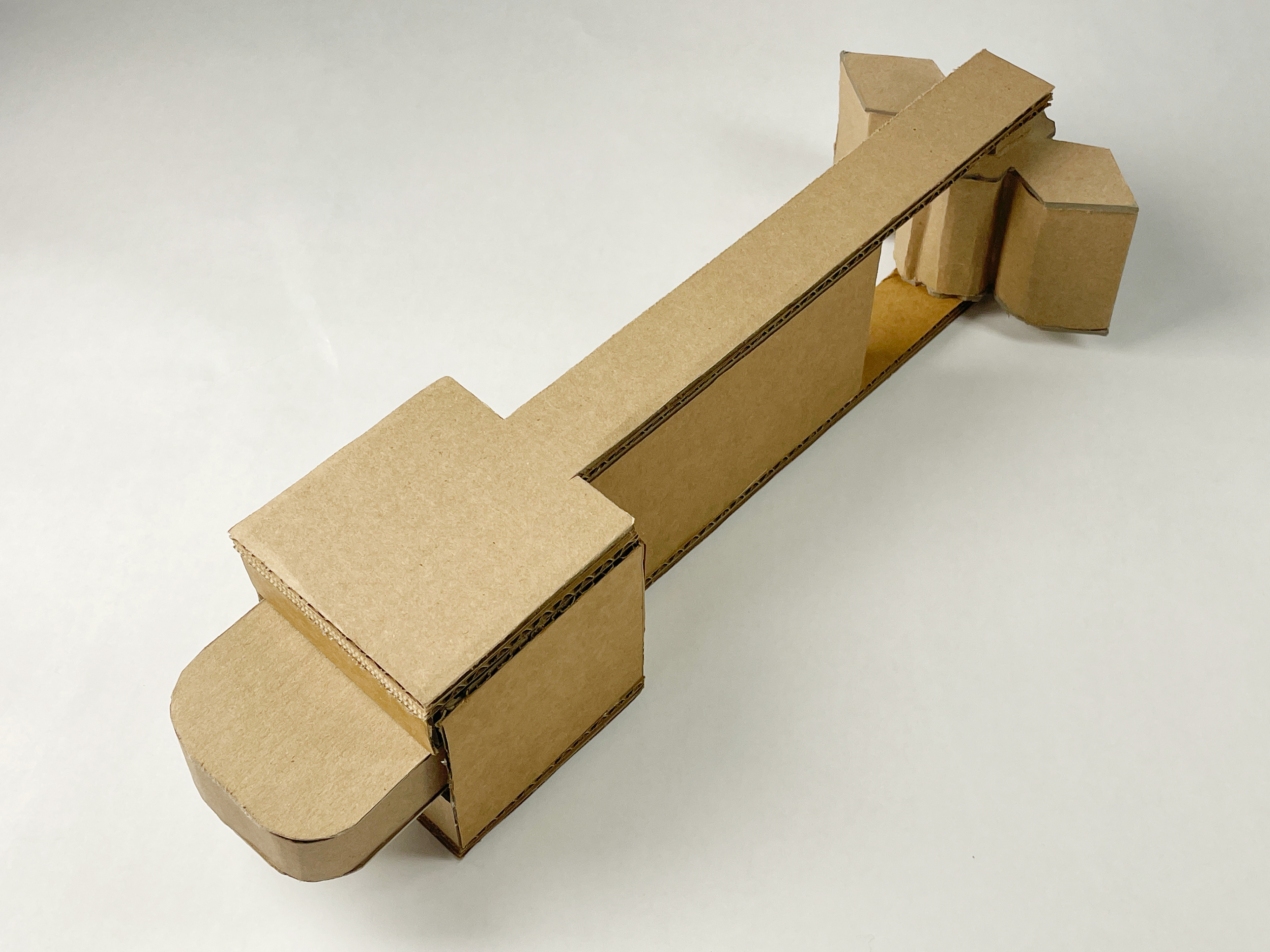

Final Connection and High-Fidelity Objects

Lessons:

- Changes in order of operations lead to certain limitations in some other of the altered operations.

- Successful build strategies include a good balance of the trade-offs of order of operations.

- There are many variables to consider when building models: the angle at which you cut, human error, scoring marks, amount of passes, thickness — that must be considered to build effective models.

- There are always solutions to each problem we face during the construction process.

- Changes in order of operations lead to certain limitations in some other of the altered operations.

- Successful build strategies include a good balance of the trade-offs of order of operations.

- There are many variables to consider when building models: the angle at which you cut, human error, scoring marks, amount of passes, thickness — that must be considered to build effective models.

- There are always solutions to each problem we face during the construction process.

- Manipulating, scoring, and cutting cardboard (and chipboard) to build quick, physical models that allow us to experience the object's form and function

- Group collaboration, coordination, and teamwork